Dhanya Foams specializes in the manufacturing of high-quality antistatic foams designed to protect sensitive electronic components across a wide range of applications. Our strength lies in producing foams with consistent antistatic properties that effectively dissipate electrostatic discharge (ESD), preventing damage to delicate electronics during handling, storage, and transportation. Dhanya Foams ensures their antistatic foams meet industry standards for ESD protection, offering reliable solutions for packaging, cushioning, and component separation in the electronics, semiconductor, and related industries. Our commitment to quality provides customers with peace of mind knowing their valuable electronic assets are safeguarded from electrostatic damage.

In the delicate world of electronics, the invisible threat of electrostatic discharge (ESD) can have devastating consequences, leading to component damage, latent failures, and significant financial losses. Antistatic Foam Tray Manufacturer for Electronics manufacturer Dhanya Plastics and Foams Pvt Ltd has established itself as a formidable force in manufacturing anti-static polyurethane (PU) and polyethylene (PE) foams specifically designed for the secure packaging and handling of sensitive electronic parts. Our strength in this niche stems from a deep understanding of ESD principles, meticulous material science, and a commitment to providing reliable and effective static dissipative solutions.

1. Comprehensive Understanding of ESD and Material Science:

Antistatic Foam Tray Manufacturer for Electronics, Dhanya Foams, offers more than just products—we deliver scientifically engineered protection:

- ESD Principles: We understand the mechanisms of charge generation, accumulation, and discharge, and how materials with controlled surface resistivity can prevent or dissipate static electricity.

- Conductive, Dissipative, and Static-Shielding Materials: Dhanya Foams likely offers a range of anti-static PU foam options, including conductive foams (very low resistance for rapid charge dissipation), dissipative foams (controlled resistance for safe charge decay), and potentially static-shielding foams (offering a Faraday cage effect).

- Polymer Chemistry and Additives: Our material scientists understand how incorporating specific additives into the PU and PE foam matrices can impart permanent or long-lasting anti-static properties without compromising the foam’s physical characteristics.

- Surface Resistivity Control: A critical parameter for anti-static foams, Dhanya Foams likely has precise control over the surface resistivity of our foams, ensuring we fall within the required ranges for effective ESD protection according to industry standards.

2. Tailored Anti-Static Foam Solutions for Diverse Electronic Components:

As a dedicated Antistatic Foam Tray Manufacturer for Electronics, Dhanya Foams customizes our offerings to suit the unique needs of different electronic parts:

- Density and Cushioning Properties: We can manufacture anti-static foams in various densities to provide the necessary physical protection and cushioning for delicate components during transit and handling.

- Die-Cutting Precision: Our expertise in die-cutting allows us to create custom inserts, trays, and packaging with precise cavities that securely hold specific electronic parts, minimizing movement and potential damage.

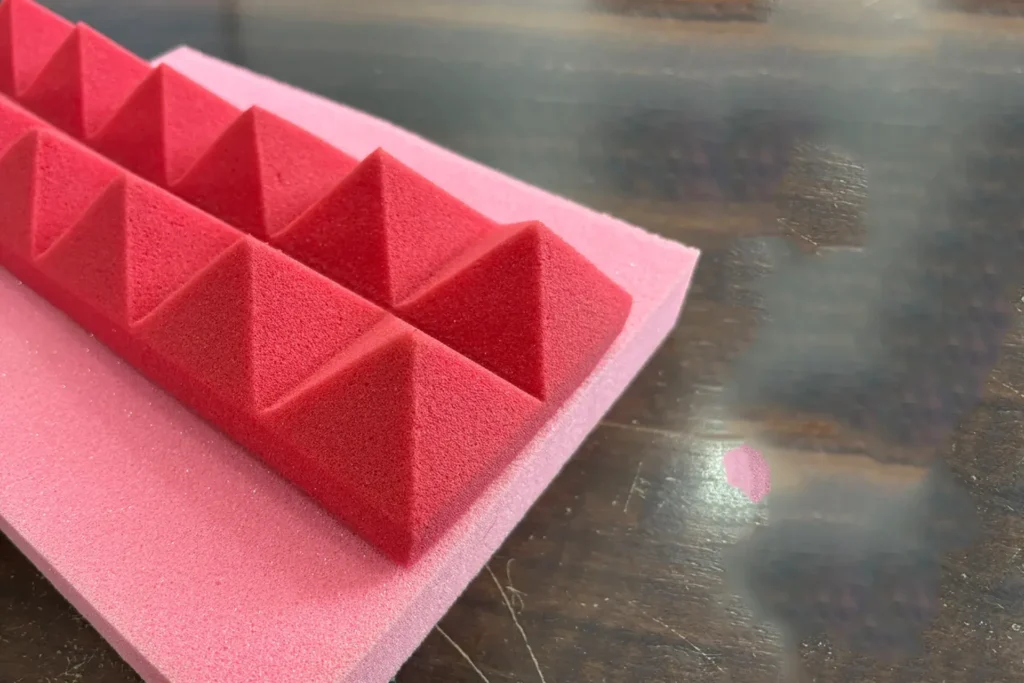

- Convoluted (Egg-Crate) and Profiled Designs: These designs maximize surface contact and provide excellent cushioning while maintaining anti-static properties. Dhanya Foams can produce these intricate shapes with accuracy.

- Laminated and Multi-Layered Solutions: For enhanced protection, we can offer laminated foams with conductive or dissipative layers combined with cushioning layers.

- Color-Coding and Identification: We can offer color-coded anti-static foams (e.g., pink for dissipative, black for conductive) for easy identification and adherence to handling protocols.

3. Stringent Manufacturing Processes and Quality Control:

Ensuring the consistent anti-static performance of our foams requires meticulous manufacturing and quality assurance:

- Controlled Additive Incorporation: Precise metering and mixing of anti-static additives are crucial for uniform and reliable performance throughout the foam material. Dhanya Foams likely employs strict controls over this process.

- Clean Manufacturing Environment: To prevent contamination that could affect the anti-static properties, our manufacturing facilities likely adhere to clean environment protocols.

- Surface Resistivity Testing: Rigorous testing of each batch of anti-static foam to verify that it meets the specified surface resistivity ranges is paramount. Dhanya Foams likely has in-house testing capabilities and follows industry-standard test methods.

- Traceability and Documentation: Maintaining detailed records of material batches and testing results ensures traceability and accountability for the anti-static properties of our foams.

4. Compliance with Industry Standards:

Dhanya Foams likely manufactures our anti-static foams to meet relevant industry standards for ESD protection, such as:

- EIA-541 (Packaging Material Standards for ESD Sensitive Items): This standard provides guidelines for the properties and testing of packaging materials used for electronic components.

Compliance with these standards provides assurance to electronics manufacturers that Dhanya Foams’ packaging solutions offer the necessary level of ESD protection.

5. Customization and Collaborative Approach:

Dhanya Foams likely works closely with electronics manufacturers to understand our specific packaging needs and component sensitivities, offering tailored solutions:

- Design Consultation: Our experts can advise on the most appropriate anti-static foam type, density, and design for specific applications.

- Prototyping and Sampling: Providing samples and prototypes allows customers to test the suitability and effectiveness of the anti-static foam packaging with our components.

- Just-in-Time Delivery: Understanding the fast-paced nature of electronics manufacturing, we offer flexible delivery options to meet production schedules.

Applications in the Electronics Industry:

Dhanya Foams’ anti-static foams are crucial for packaging and handling a wide range of electronic components, including:

- Integrated Circuits (ICs)

- Printed Circuit Boards (PCBs)

- Semiconductors

- Microprocessors

- Diodes and Transistors

- Surface Mount Devices (SMDs)

- Connectors

- Sensitive Assemblies

Dhanya Foams’ strength in manufacturing anti-static foam for electronic parts packaging lies in our comprehensive understanding of ESD, our ability to tailor foam properties and designs, our rigorous manufacturing and quality control processes, our commitment to industry standards, and our collaborative approach with customers. By providing reliable and effective static dissipative packaging solutions, Dhanya Foams plays a vital role in protecting sensitive electronic components throughout the supply chain, minimizing damage, ensuring product reliability, and safeguarding the investments of electronics manufacturers. We are not just selling foam; we are providing peace of mind in a world vulnerable to the silent threat of static electricity.

Frequently Asked Questions

Antistatic Polyurethane (PU) foam is a specialized open-cell foam designed to dissipate electrostatic charges, protecting sensitive electronic components from electrostatic discharge (ESD) damage

It incorporates conductive or dissipative additives that allow static electricity to flow through the foam, neutralizing charges and preventing accumulation that could harm electronic devices.

Common uses include packaging for electronic components, cushioning for circuit boards, lining for shipping containers, and protective inserts for sensitive devices.

Yes, it is available in various densities, commonly ranging from 15 to 35 kg/m³, to suit different cushioning and protection needs.

Absolutely. It can be cut, molded, or fabricated into specific dimensions and shapes to fit particular applications or products.

Typically, it comes in black or pink, which are standard colors indicating antistatic properties.

Store in a dry, cool environment away from direct sunlight to maintain its antistatic properties and structural integrity.

Yes, its low particulate generation and antistatic properties make it suitable for cleanroom applications where contamination control is critical.

- Antistatic foam: Prevents static buildup but doesn’t conduct electricity.

- Conductive foam: Allows electricity to flow through it easily.

- Dissipative foam: Slows down the flow of electricity, providing controlled discharge.

The longevity depends on the type of antistatic treatment. Some foams have permanent properties, while others may degrade over time, especially with exposure to humidity and contaminants.