Vacuum Forming Moulds: Dhanya has wide-ranging experience and expertise in the design, development and procurement of prototype tools, moulding tools and assembly jigs and fixtures. For clients looking to be more creative with their products, we provide CNC machined tooling, which enables increased design complexity and enhanced finishing.

Our main tooling services include:

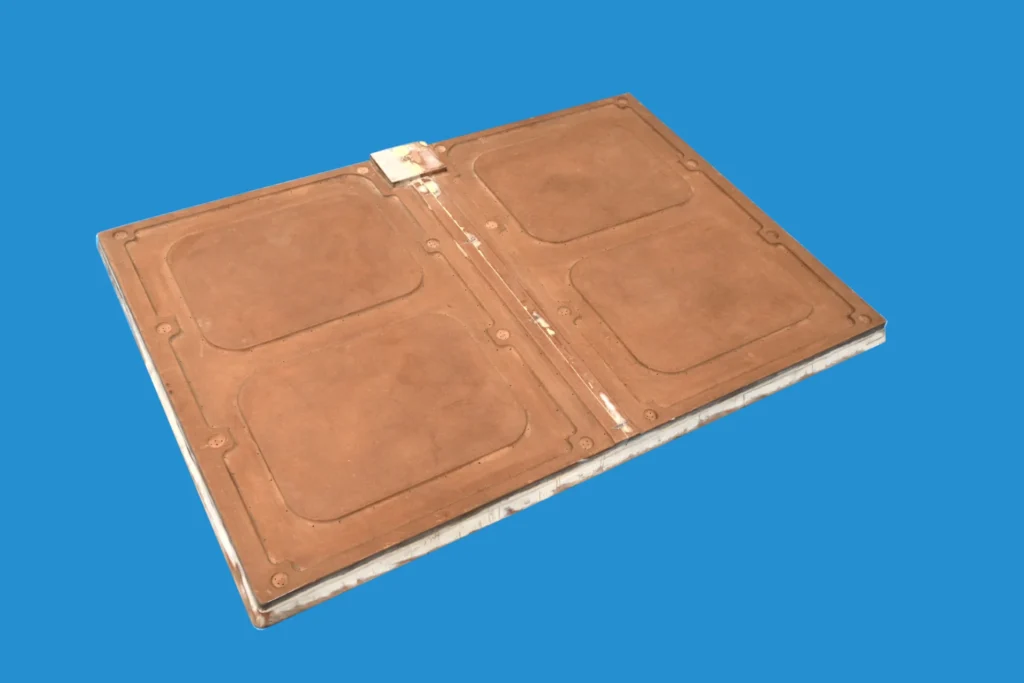

Prototype tooling development-Wooden Pattern

Prototype Tooling can be a cost effective solution when it comes to creating complex and sophisticated moulds. Prototype tooling is also useful if you need to test the functionality of your component before you move on to the production side of things, where this would involve much larger volumes of components being made.Therefore prototype tooling is more suited if you need samples or only parts of a complete product. As part of prototype tooling, factoring in the possibility of a component being altered or changed is usually part of the testing process, which should be identified early before going forward with a final product.

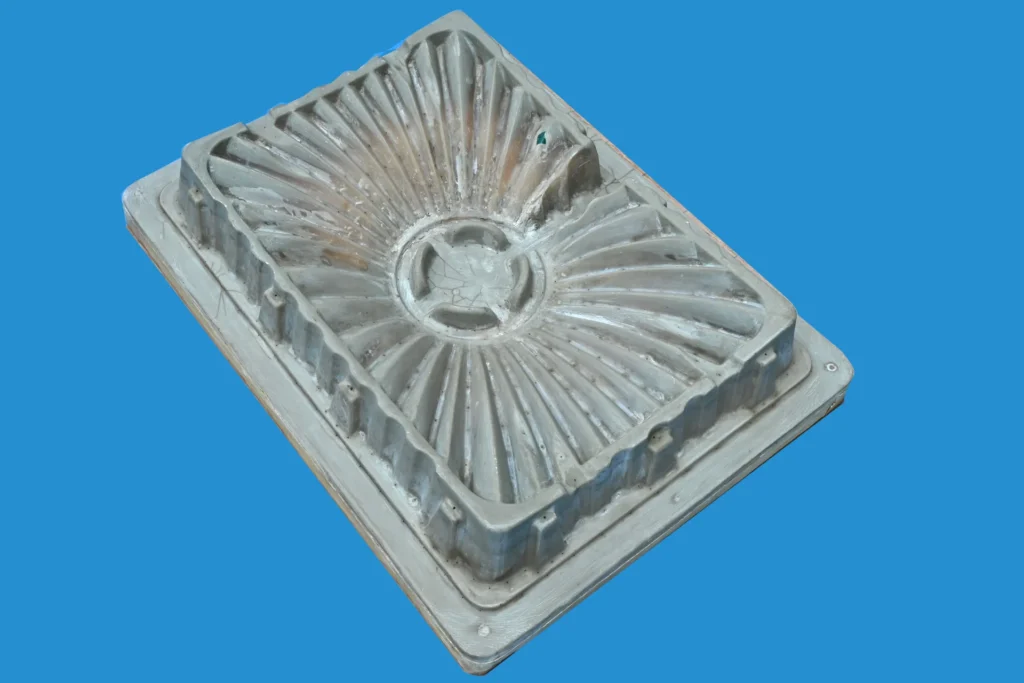

Production Tooling-Epoxy

Epoxy moulds are often used in vacuum forming due to their, High durability and resistance to heat, Ability to produce complex geometries and detailed designs, Smooth surface finish, which helps prevent defects in the formed parts, Cost-effectiveness for medium volume production runs and also the best for reverse engineering in some cases.

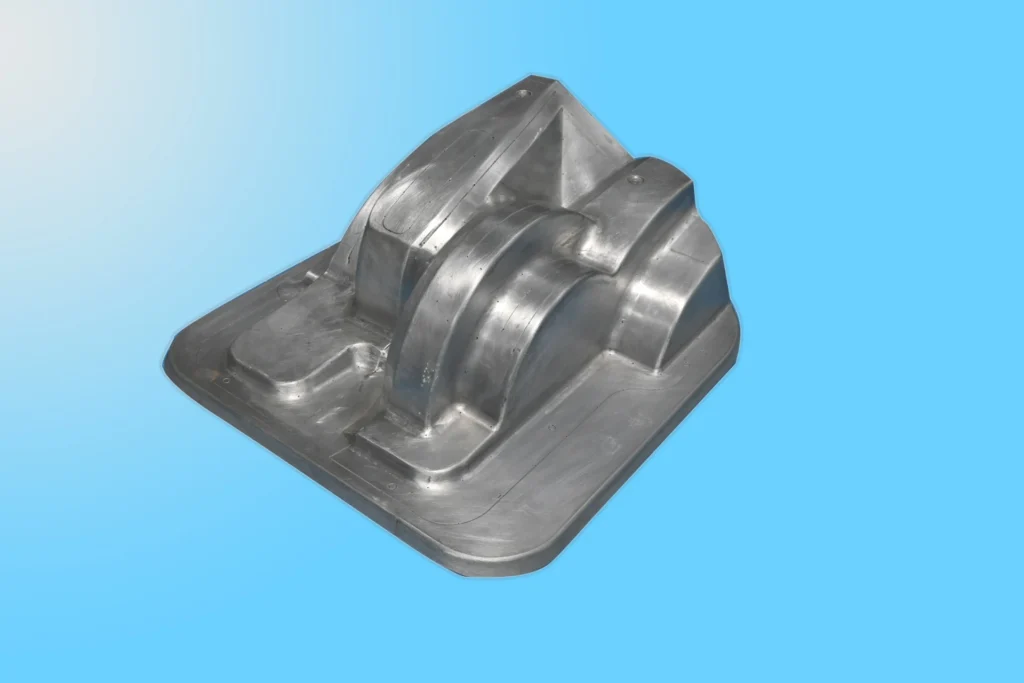

Production Tooling-Aluminium

Aluminum moulds are commonly used in vacuum forming due to their:- High thermal conductivity, allowing for efficient heat transfer, Lightweight and durable construction, Ability to produce high-quality parts with precise details, Cost-effectiveness for high-volume production runs and also on the increaased mould lifespan.

Frequently Asked Questions

Plastic mould manufacturing involves designing and producing precision moulds (e.g., injection, blow, or compression moulds) used to shape molten plastic into components. It’s critical for mass-producing parts with high consistency and efficiency.

- Injection Moulds: For high-volume parts like housings and containers.

- Blow Moulds: For hollow items like bottles.

- Compression Moulds: For thermosets like silicone or epoxy.

- Prototype Moulds: Low-cost aluminium moulds for testing.

- Tool Steel: H13, P20 for durability and heat resistance.

- Aluminium: For prototypes or short runs.

- Beryllium Copper: For high heat dissipation in complex parts.

- Automotive: Dashboards, light housings.

- Medical: Syringes, IV components.

- Consumer Goods: Packaging, toys.

- Electronics: Connectors, device casings.

- Cost-Effective at Scale: Lower per-unit costs for 1,000+ units.

- Surface Finish: Smoother, production-ready parts.

- Material Range: Supports engineering-grade plastics like PEEK or PC.

- Prototype Moulds: 4–6 weeks (aluminium).

- Production Moulds: 8–12 weeks (steel).

Yes. High initial tooling costs are offset by low per-part pricing in bulk orders (10,000+ units).

- Hardening/Tempering: Enhances steel durability.

- CNC Machining: Precision cavities and cores.

- Testing: Trial runs to validate part quality.

3D CAD files in STEP, IGES, or STL formats, with draft angles and wall thickness specifications.

- Design Simplification: Avoid undercuts and thin walls.

- Aluminium Moulds: For prototypes or small batches.

- Standardized Components: Use existing mould bases.