Dhanya Foams specializes in manufacturing high-strength reticulated filter foams engineered to meet diverse filtration standards across various applications. Our strength lies in producing foams with a consistent, open-cell structure that provides optimal airflow while effectively trapping particulate matter. By adhering to industry filtration standards and employing rigorous quality control, Dhanya Foams ensures their reticulated foams offer reliable performance and durability in applications ranging from air and fluid filtration to pre-filters and acoustic damping. Our commitment to consistent quality and filtration efficiency makes them a trusted supplier for numerous industrial and consumer needs.

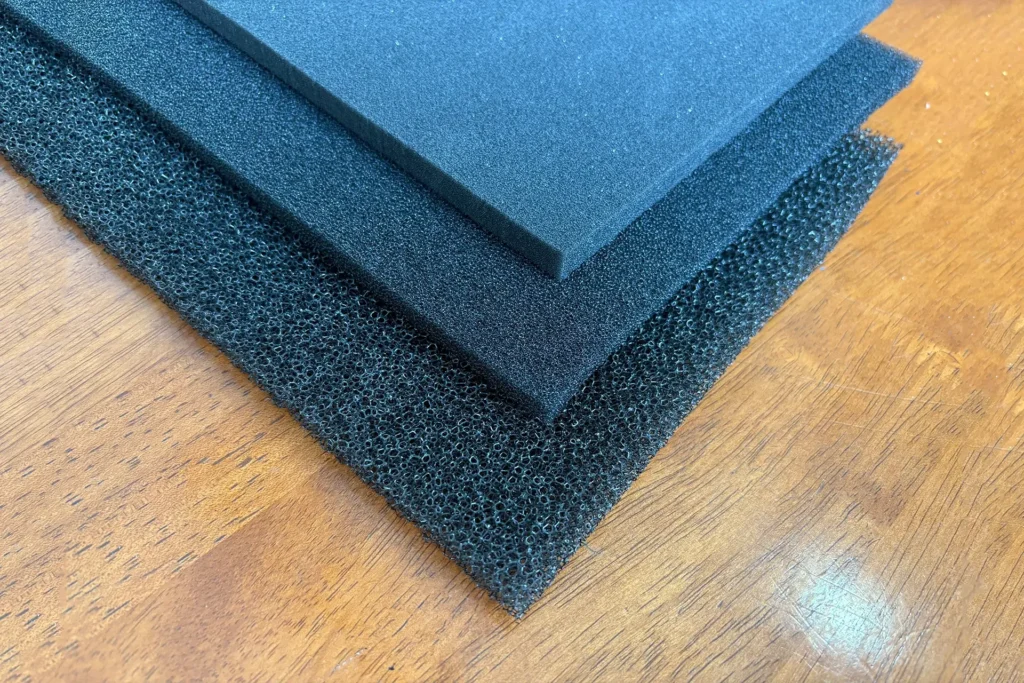

Reticulated filter foam, often called “open-cell” or “netted” foam, is a unique material with a skeletal, interconnected structure. Unlike traditional foam with closed or partially open cells, reticulated foam undergoes a special manufacturing process that removes the cell walls, leaving behind a three-dimensional network of robust struts. This distinctive structure imbues it with a remarkable combination of properties, making it an indispensable component across a surprisingly diverse range of industries.

Dhanya Plastics and Foams Pvt Ltd, with its expertise in polyurethane and polyethylene foams, is well-positioned to manufacture and supply high-quality reticulated filter foam for industrial applications tailored to the specific demands of various sectors. Let’s delve into the widespread applications of this versatile material:

The Defining Characteristics of Reticulated Filter Foam:

Before exploring its uses, understanding the key properties of reticulated filter foam for industrial applications is crucial:

- High Porosity (Open Cell Structure): This is the defining characteristic, allowing for the unrestricted flow of air and liquids while effectively trapping particulate matter.

- Low Flow Resistance: Despite its filtration capabilities, it offers minimal resistance to the passage of fluids or air.

- Large Surface Area: The interconnected skeletal structure provides a vast surface area for filtration, microbial colonization (in biological filters), or other surface-dependent processes.

- Lightweight: Despite its strength and durability, reticulated foam is remarkably lightweight.

- Durability and Resilience: The interconnected struts provide good structural integrity and resistance to tearing and compression.

- Washability and Reusability: Many reticulated filter foams for industrial applications can be easily cleaned and reused, offering a cost-effective and sustainable solution.

- Chemical Resistance: Depending on the base polymer (polyether or polyester), reticulated foams can exhibit good resistance to various chemicals, solvents, and fuels.

- Customizability: It can be easily die-cut, shaped, and fabricated into various forms to fit specific applications. Pore size (measured in PPI – pores per inch) can be controlled during manufacturing to fine-tune filtration efficiency and flow rate.

- Anti-Microbial Properties (inherent or added): The open-cell structure promotes air circulation, hindering moisture build-up and the growth of mold and mildew. Anti-microbial additives can further enhance this property.

A Spectrum of Applications Across Industries:

The unique combination of these properties makes reticulated filter foam a vital component in numerous industries:

1. Filtration (Air, Water, and Other Fluids): This is arguably the most widespread application:

- HVAC (Heating, Ventilation, and Air Conditioning): As pre-filters and primary filters in air conditioning units, air purifiers, and ventilation systems to remove dust, pollen, and other airborne particles, ensuring clean air circulation.

- Automotive: In air intake filters for engines, cabin air filters to improve in-car air quality, and fuel filters to prevent clogging.

- Water Treatment: For pre-filtration in water purification systems, aquarium filters (biological and mechanical filtration), pond filters, and industrial water filtration processes.

- Medical: In respiratory devices, CPAP machine filters, and wound dressings where air permeability and fluid absorption are crucial.

- Industrial Processes: Filtering oils, solvents, paints, and other industrial fluids to remove contaminants and protect equipment.

- Small Engines and Compressors: As air filters to protect internal components from dust and debris.

- Vacuum Cleaners and Dust Bags: As filters to capture dust and allergens.

2. Acoustics: While not a sound barrier, reticulated foam excels at sound absorption:

- Audio and Recording Studios: As acoustic panels and bass traps to control sound reflections and reverberation, improving audio quality.

- Automotive and Aerospace: For noise reduction in vehicle interiors and aircraft cabins.

- Industrial Equipment: Lining enclosures and machinery to absorb sound waves and reduce noise pollution.

- Consumer Electronics: In speaker grills and microphone windscreens to protect components while minimizing acoustic interference.

3. Fluid Management: The absorbent and permeable nature of reticulated foam makes it ideal for:

- Ink Reservoirs: In pens, printers, and stamp pads for controlled ink release.

- Medical Devices: In wound dressings for fluid absorption and promoting airflow.

- Cosmetic Applicators: In sponges and pads for even application of makeup.

- Fuel Tank Safety: Specialized reticulated foams are used in fuel tanks to suppress explosions by limiting fuel sloshing and creating a vapor barrier.

4. Padding and Cushioning: The resilience and open-cell structure provide comfortable and breathable padding:

- Outdoor Furniture: In cushions and padding where quick drying and resistance to mildew are essential.

- Sports Equipment: In padding for helmets, knee pads, and other protective gear.

- Shoe Inserts: Providing cushioning and breathability.

- Packaging: As custom inserts for protecting delicate items during shipping.

5. Cleaning and Wiping: The durable and absorbent nature makes it suitable for:

- Sponges and Scrubbers: For household and industrial cleaning.

- Wiping Cloths: Especially in cleanroom environments where low linting is required (depending on the specific foam type).

6. Other Specialized Applications:

- Ceramic Foam Filters: Reticulated foam is used as a template in the manufacturing of ceramic filters for molten metal filtration.

- Catalyst Carriers: The high surface area provides an excellent substrate for catalysts in various chemical processes.

- Battery Electrodes: In some advanced battery technologies.

- Humidifier Pads: For controlled release of moisture into the air.

Dhanya Foams: Your Partner in Reticulated Foam Solutions:

Dhanya Foams, with its expertise in polyurethane and polyethylene foam manufacturing, can provide tailored reticulated filter foam solutions to meet the specific requirements of your industry. Our capabilities likely include:

- Wide Range of Base Polymers: Offering reticulated foams in various PU (polyether and polyester) and PE grades to match chemical resistance, flexibility, and durability needs.

- Controlled Pore Sizes (PPI): Manufacturing foams with specific PPI values to optimize filtration efficiency and flow rates for your application.

- Custom Die-Cutting and Fabrication: Creating precisely shaped components and inserts to seamlessly integrate into your products or systems.

- Adhesive Backing and Lamination: Adding adhesive layers for easy installation or laminating with other materials for enhanced functionality.

- Anti-Microbial and Other Additives: Incorporating specific additives to enhance the foam’s properties for specialized applications.

- Quality Assurance: Ensuring consistent quality and performance of our reticulated filter foam products.

Reticulated filter foam is a truly versatile material, playing a critical yet often unseen role in a vast array of industries. Its unique open-cell structure and customizable properties make it an ideal solution for filtration, acoustics, fluid management, padding, and more. As industries continue to demand efficient, durable, and often specialized materials, Dhanya Foams’ strength in manufacturing high-quality reticulated filter foam positions them as a valuable partner in providing innovative solutions for diverse applications. By understanding the specific needs of each industry, Dhanya Foams can engineer and deliver reticulated foam products that contribute to enhanced performance, safety, and efficiency across the board.

Frequently Asked Questions

Reticulated filter foam is a high-porosity, open-cell foam with interconnected skeletal strands, designed for optimal fluid/gas flow and particle capture. Its structure maximizes filtration efficiency while minimizing pressure drop.

- Polyurethane (PU): Most common, balancing cost and performance.

- Polyester (PET): Chemical-resistant for harsh environments.

- Polyether: Flexible and durable for repeated cleaning.

- Automotive: Air intake filters, fuel filtration.

- Aerospace: Hydraulic fluid filtration.

- Medical: Respirators, blood filtration.

- Water Treatment: Biofilters, aquaculture systems.

- High Porosity: 90–98% open cells for unrestricted flow.

- Custom PPI (Pores Per Inch): Ranges from 10 PPI (coarse) to 100 PPI (fine).

- Reusable: Withstands repeated cleaning (backwashing, solvents).

A reticulation process (thermal or chemical) removes cell membranes from foam, creating an open-cell structure ideal for trapping particles while allowing airflow.

Flame-retardant grades meet UL 94 HF-1 and FMVSS 302 standards, ideal for automotive or aerospace applications.

- Mechanical Cleaning: Compressed air or water jets.

- Chemical Soak: Mild detergents or solvents (check compatibility).

- Autoclaving: For medical-grade foam.

Yes. Foam is die-cut, molded, or laminated into cylinders, discs, or custom geometries to fit specific housings or systems.

With proper maintenance, it lasts 3–5+ years in industrial applications and indefinitely in low-particulate environments like aquariums.

- Higher Dirt-Holding Capacity: Traps more particles before clogging.

- Lower Pressure Drop: Maintains flow efficiency longer.

- Cost-Effective: Cheaper than metal sintered filters.