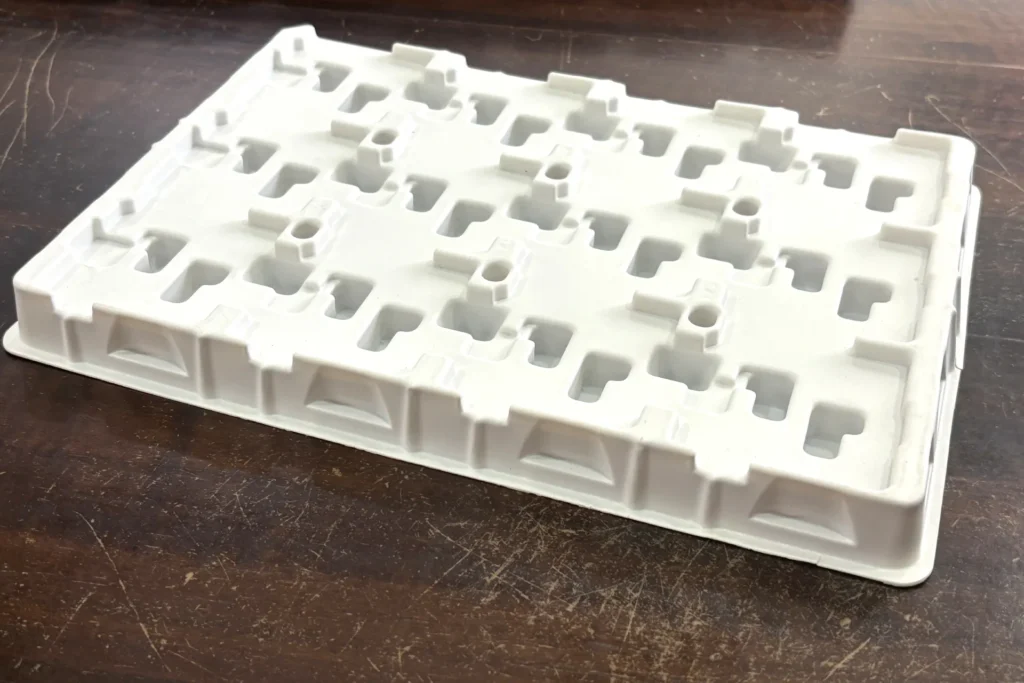

Dhanya Plastics focuses on delivering robust vacuum-formed plastic trays for packaging in both electronics and industrial sectors. Recognizing the need to protect sensitive electronic components and durable industrial parts during transit and handling, we prioritize the strength and structural integrity of trays. By selecting appropriate plastic materials with good impact resistance and employing precise vacuum forming techniques, Dhanya Plastics ensures these trays can securely hold and protect their contents. This emphasis on strength minimizes the risk of damage, contributing to efficient and secure packaging solutions for diverse applications.

In the intricate dance of modern logistics and supply chains, efficient and reliable packaging plays a pivotal role. Packing trays, often the unsung heroes, ensure the safe and organized transit of goods across diverse industries. Dhanya Plastics and Foams Pvt Ltd has established itself as a formidable force in manufacturing high-quality packing trays through our deep expertise in thermoforming, providing solutions that streamline operations and protect products.

But what makes Dhanya Plastics a leader in the realm of Thermoforming Plastic Trays? It’s our masterful command of the thermoforming process, our versatility in material selection, our focus on customized solutions, and our unwavering commitment to delivering efficiency and reliability. Let’s unpack the details of our strengths:

1. The Art and Science of Thermoforming for Optimal Packing Trays:

Dhanya Plastics possesses a profound understanding of the thermoforming process, leveraging its capabilities to create Thermoforming Plastic Trays that meet a wide spectrum of needs:

- Precision and Consistency: Thermoforming allows for the creation of trays with precise cavity dimensions and consistent shapes, ensuring a secure and organized fit for the products we hold. Dhanya Plastics’ advanced equipment and skilled technicians guarantee dimensional accuracy in every tray.

- Durability and Structural Integrity: Thermoforming Plastic Trays often need to withstand stacking, handling, and the weight of the goods we contain. Dhanya Plastics optimizes the thermoforming process and material selection to produce trays with excellent structural integrity and durability, minimizing damage during transit and storage.

- Customizable Designs: One size rarely fits all in the world of packaging. Thermoforming offers significant design flexibility, allowing Dhanya Plastics to create trays with specific cavity layouts, depths, and features tailored to the exact dimensions and requirements of the products being packaged. This includes trays for delicate electronics, irregularly shaped components, and multi-part kits.

- Efficient Production for Volume Needs: Thermoforming is a highly efficient manufacturing process, particularly for medium to high volumes. Dhanya Plastics’ streamlined operations ensure timely production and delivery of large quantities of Thermoforming Plastic Trays to meet the demands of diverse industries.

- Lightweight Yet Robust Solutions: Thermoforming Plastic Trays offer a balance of being lightweight for ease of handling and cost-effective shipping, while still providing the necessary rigidity and protection for the contents. Dhanya Plastics optimizes material usage to achieve this ideal balance.

2. A Material Palette Tailored for Diverse Packing Needs:

Dhanya Plastics expertly works with a variety of thermoplastics, selecting the ideal material based on the specific requirements of the application:

- PET (Polyethylene Terephthalate): Known for its strength, clarity, and recyclability, PET is a popular choice for Thermoforming Plastic Trays for consumer goods, electronics, and food items where visibility and environmental considerations are important.

- PVC (Polyvinyl Chloride): Offering good rigidity and chemical resistance, PVC is often used for industrial and hardware packing trays. Dhanya Plastics ensures our PVC trays meet relevant industry standards.

- PS (Polystyrene): Lightweight and cost-effective, PS is widely used for protective packaging inserts, cushioning trays, and disposable trays for various applications.

- PP (Polypropylene): Valued for its durability, chemical resistance, and ability to withstand varying temperatures, PP is suitable for packing trays for automotive parts, medical devices, and some food applications.

- HDPE (High-Density Polyethylene): Known for its strength and impact resistance, HDPE is used for heavier-duty packing trays for industrial components and material handling.

- ABS (Acrylonitrile Butadiene Styrene): Offering a balance of strength, impact resistance, and good aesthetics, ABS is used for more demanding packing tray applications, including those requiring a specific visual appeal.

3. Engineering Efficiency through Customized Packing Tray Solutions:

Dhanya Plastics goes beyond simply forming plastic; we engineer efficiency into our packing tray solutions through:

- Product-Specific Cavity Design: Our design team collaborates closely with clients to create trays with cavities that precisely fit and protect the products being packaged, minimizing movement and potential damage during transit.

- Stackability and Nestability: Dhanya Plastics designs trays for optimal stacking and nesting, maximizing space utilization during storage and transportation, ultimately reducing logistics costs.

- Ergonomic Features: For trays that require manual handling, Dhanya Plastics can incorporate ergonomic features like handles or finger grips to improve ease of use and reduce operator fatigue.

- Integration with Automation: Understanding the increasing use of automation in packaging lines, Dhanya Plastics designs trays that are compatible with automated loading and unloading systems, streamlining the packaging process.

- Protective Features: Depending on the sensitivity of the products, Dhanya Plastics can incorporate features like anti-static properties for electronics, cushioning elements, or dividers for secure separation.

4. Serving a Wide Spectrum of Industries with Tailored Packing Solutions:

Dhanya Plastics’ expertise in thermoformed packing trays caters to a diverse range of industries, including:

- Electronics: Manufacturing trays for organizing and protecting delicate electronic components during assembly and shipping.

- Automotive: Producing trays for transporting and staging automotive parts within manufacturing facilities and to assembly lines.

- Medical Devices: Creating trays for sterilizing and packaging medical instruments and devices, adhering to stringent hygiene standards.

- Consumer Goods: Designing trays for retail packaging, kitting, and organizing various consumer products.

- Food and Beverage: Manufacturing trays for transporting and displaying food items, ensuring freshness and presentation.

- Industrial and Manufacturing: Producing material handling trays for organizing and transporting industrial parts and components.

5. Commitment to Quality, Reliability, and Timely Delivery:

Dhanya Plastics understands that efficient packaging is time-sensitive and quality-dependent:

- Stringent Quality Control: Implementing rigorous quality checks throughout the thermoforming process to ensure dimensional accuracy, material integrity, and overall durability of the trays.

- Reliable Production Capabilities: Leveraging efficient manufacturing processes and a skilled workforce to ensure consistent production and timely delivery of orders.

- Customer-Centric Approach: Working closely with clients to understand our specific needs and provide tailored solutions that meet our requirements and timelines.

Dhanya Plastics stands as a strong and reliable partner for businesses seeking high-quality thermoformed packing trays. Our mastery of the thermoforming process, coupled with our material versatility, focus on customization, and commitment to efficiency and quality, makes them a leader in this critical aspect of the supply chain. By providing tailored packing solutions that protect products, optimize logistics, and streamline operations, Dhanya Plastics plays a vital role in helping businesses across diverse industries achieve greater efficiency and success. When it comes to packing trays that deliver on both performance and reliability, Dhanya Plastics shapes the future of efficient packaging.

Frequently Asked Questions

Vacuum forming is a manufacturing process where a plastic sheet is heated until pliable, then shaped over a mold using vacuum pressure. In packaging, this technique produces custom trays and containers that securely hold products, especially useful for electronics and industrial components.

Vacuum-formed packaging offers precise fit and protection, ensuring that sensitive electronic components and durable industrial parts remain secure during transit and handling. The strength and structural integrity of these trays minimize the risk of damage.

Common materials include High Impact Polystyrene (HIPS), Acrylonitrile Butadiene Styrene (ABS), and Polyethylene Terephthalate Glycol (PETG). These materials are selected for their durability, impact resistance, and suitability for specific applications.

Yes, vacuum forming allows for high customization. Trays can be designed to match exact product dimensions, ensuring a snug fit and optimal protection.

Many vacuum-formed trays are designed for multiple uses and are recyclable, depending on the material used. This makes them both cost-effective and environmentally friendly.

Lead times can vary based on design complexity and order volume. However, vacuum forming generally offers quicker turnaround times compared to other manufacturing methods.

Yes, materials with anti-static properties can be used in vacuum forming to protect sensitive electronic components from electrostatic discharge.

Absolutely. Logos, part numbers, and other branding elements can be integrated into the mold design, allowing them to be embossed or debossed onto the trays.

While vacuum forming is commonly used for food packaging, it’s essential to use food-grade materials and comply with relevant regulations.

Vacuum forming is typically more cost-effective for low to medium production volumes and offers faster prototyping. Injection moulding, while suitable for high-volume production, involves higher initial tooling costs and longer lead times.