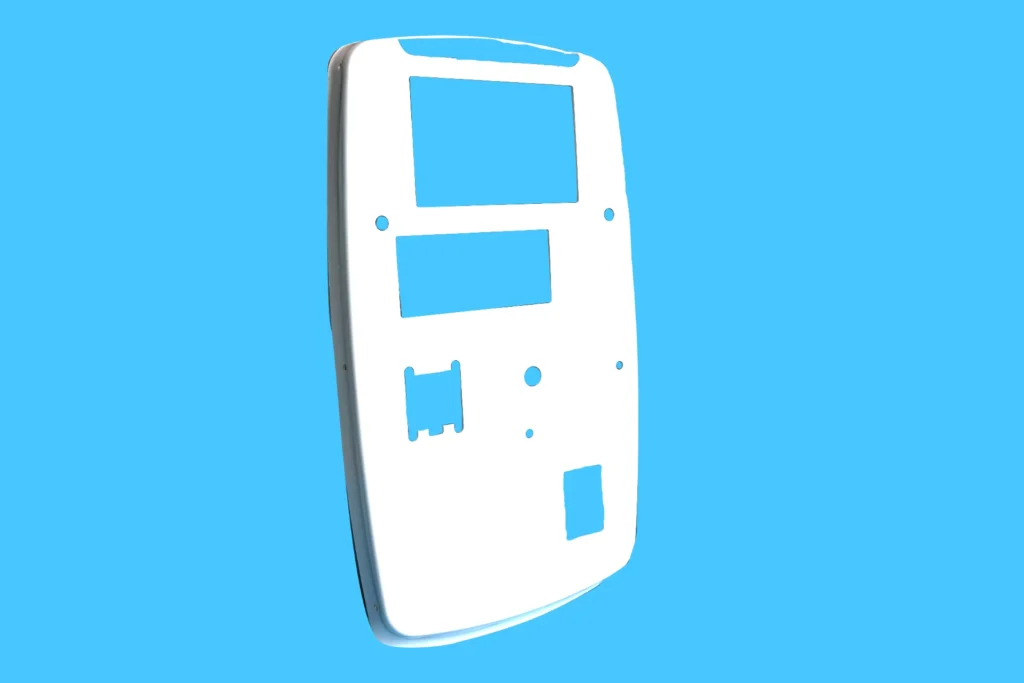

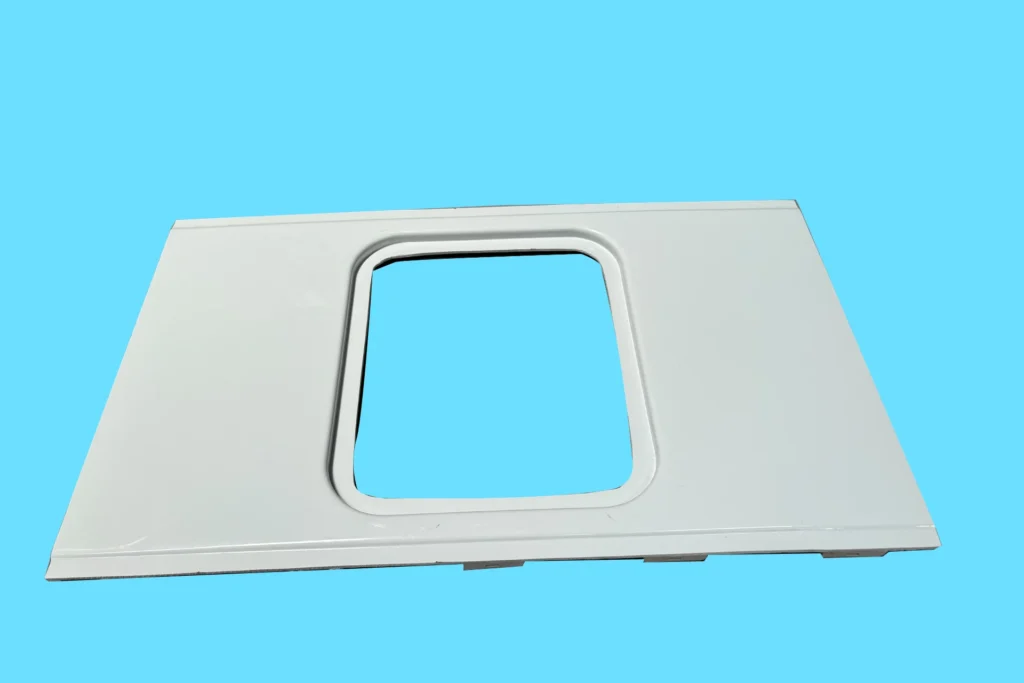

Dhanya Plastics understands the critical requirement for robust strength in vacuum-formed plastic panels used in medical equipment machines. These panels often serve as protective housings or structural components and must withstand regular use and cleaning. By carefully selecting durable, medical-grade plastics and employing precise vacuum forming techniques, Dhanya Plastics ensures these panels possess the necessary impact resistance and structural integrity. This focus on strength contributes to the overall reliability and longevity of vital medical equipment, ultimately supporting patient care.

Frequently Asked Questions

Yes. Optical-grade acrylic and PETG provide clarity for devices like endoscope housings, fluid reservoirs, or light-guided surgical tools.

Materials like polypropylene (PP) and PETG are autoclave-, gamma-, or ETO-compatible, retaining structural integrity after repeated sterilization cycles.

- Single-use devices: Sterile packaging, biopsy trays.

- Diagnostic tools: Test cartridge housings, microfluidic chips.

- Durable equipment: Monitor panels, ventilator components.

- Anti-microbial coatings (e.g., silver-ion infused).

- Smooth, non-porous finishes that resist biofilm formation.

- Cleanroom production to eliminate contaminants.

Yes. Insert molding embeds electronics during forming for smart devices like IoT-enabled drug dispensers or temperature-sensitive storage units.

- Lower tooling costs vs. injection moulding (aluminum molds vs. steel).

- Rapid prototyping for design validation.

- Minimal material waste with nesting optimization.

Yes. Recycled PETG (FDA-approved) is used for packaging trays or non-sterile storage bins, paired with virgin-material barriers for safety.

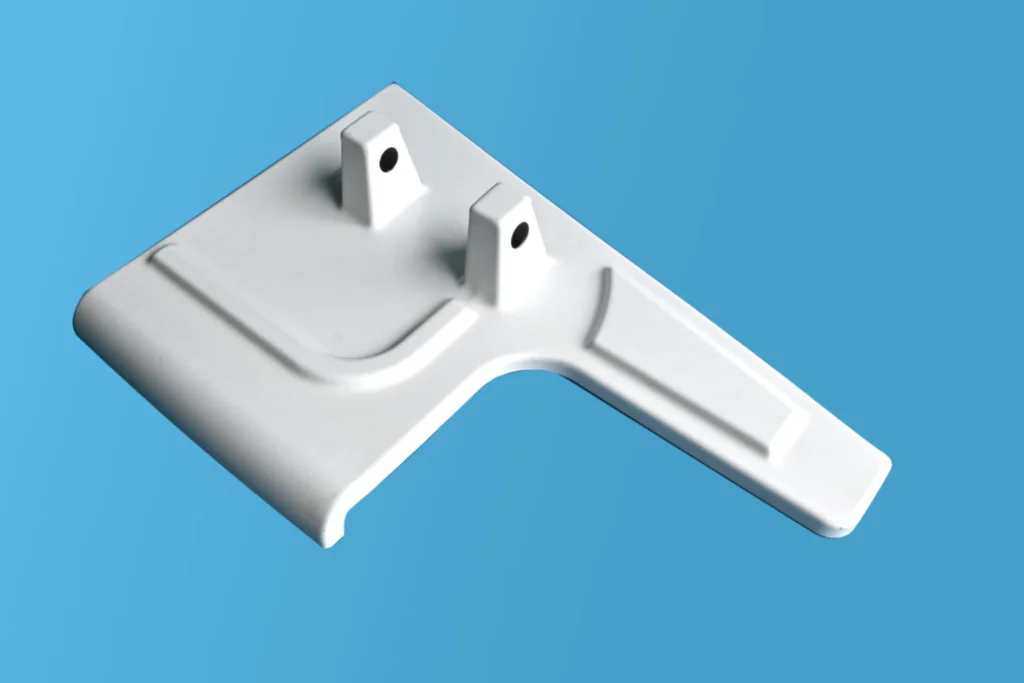

Yes. Mold textures create anti-slip surfaces for ergonomic scalpel handles or forceps, enhancing surgeon comfort and precision.

- Seamless, waterproof designs (no joints or seams).

- Faster production for batches of 100–5,000 units.

- Cost savings on complex geometries.

- Hybrid molds for multi-material components (e.g., rigid frames with soft seals).

- Smart sensors embedded during forming.

- Biodegradable plastics for eco-conscious disposables.