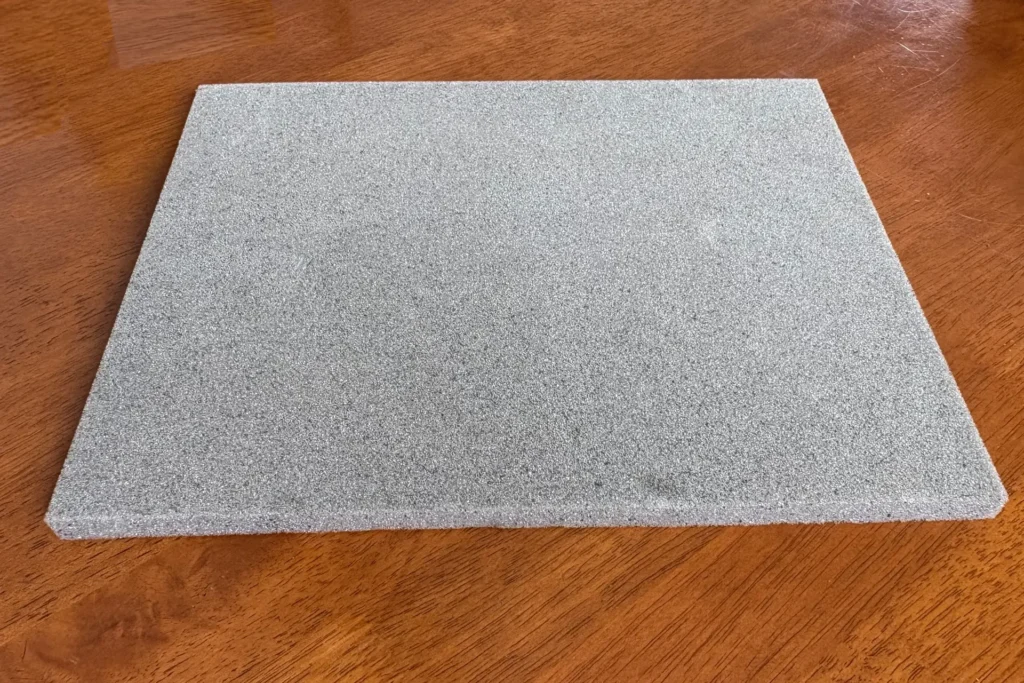

Dhanya Foams demonstrates strength in manufacturing lightweight foams specifically engineered for NVH (Noise, Vibration, and Harshness) applications within the automotive industry. we excel at producing foams that effectively dampen unwanted sounds and vibrations without adding significant weight to the vehicle. By carefully controlling the foam’s density and cell structure, Dhanya Foams ensures optimal NVH performance while contributing to fuel efficiency. Our lightweight foams meet stringent automotive standards for durability and acoustic performance, providing effective solutions for a quieter and more comfortable driving experience.

Frequently Asked Questions

Lightweight foam for NVH (Noise, Vibration, and Harshness) reduces unwanted sound and vibrations in vehicles/machinery using low-density, high-damping materials like polyurethane (PU) or EVA foam. It improves passenger comfort and meets stringent automotive/aerospace weight-saving goals.

- Polyurethane (PU) Foam: Flexible, with excellent sound absorption.

- Melamine Foam: Fire resistant and heat-tolerant for engine bays.

- EPDM Rubber Foam: Durable for sealing and vibration damping.

- Acrylic Foam Tapes: Adhesive solutions for panel bonding.

- Automotive: Dashboards, door panels, engine covers.

- Aerospace: Cabin insulation, cargo liners.

- Industrial: Machinery housings, HVAC systems.

- Consumer Electronics: Appliance noise reduction.

- Airborne Noise: Open-cell structures absorb sound waves (e.g., cabin noise).

- Structure-Borne Vibrations: Viscoelastic properties dampen vibrations (e.g., engine mounts).

Yes. Silicone-based foams handle -50°C to 140°C, while closed-cell PU foams resist oils, fuels, and solvents.

- Weight: Foam is 30–50% lighter than rubber.

- Design Flexibility: Easily molded into complex shapes.

- Cost: Lower material and assembly costs for high-volume production.

- Recycled Content: Post-industrial PU/EVA foam for non-critical parts.

- Biodegradable Options: Plant-based foams under development.

- REACH/ROHS Compliance: Safe for EU markets.

- Adhesive Backing: Pre-applied tapes for panels.

- Mechanical Fasteners: Clips or bolts for heavy-duty parts.

- Spray Applications: Liquid foam for seamless cavity filling.

Yes. Die-cutting, overmolding, and multi-layer laminates create custom seals, isolators, or acoustic barriers tailored to OEM specifications.

- Weight Reduction: Extends battery range.

- Quiet Cabins: Compensates for lack of engine noise.

- Thermal Management: Insulates battery packs.