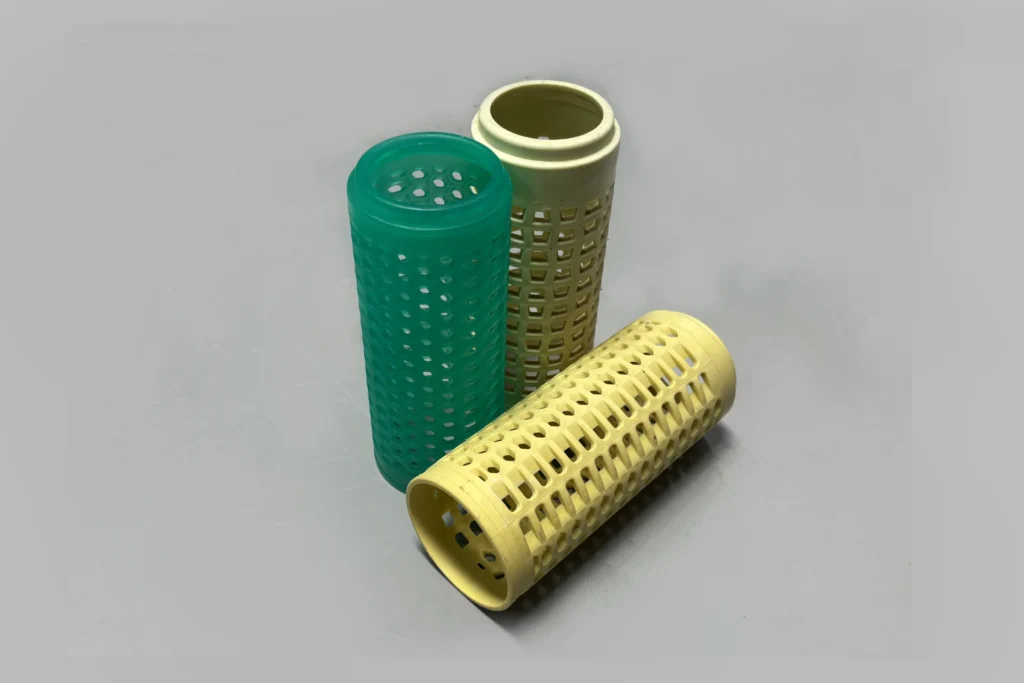

Dhanya Plastics understands the critical need for robust moulding strength in industrial products. These components often face harsh operating environments, heavy loads, and continuous use. Therefore, Dhanya Plastics prioritizes the selection of high-performance polymers and employs advanced injection moulding techniques to manufacture parts that exhibit exceptional durability and resistance to wear, impact, and chemical exposure. Our commitment to stringent quality control ensures industrial plastic components consistently meet the demanding performance requirements of various industrial applications, contributing to operational reliability and longevity.

Frequently Asked Questions

A manufacturing process that produces high-strength, precision plastic or composite parts for industrial machinery, enclosures, tools, and equipment using custom molds and high-pressure material injection.

Injection moulding costs range from 1,000–100,000+, depending on:

- Tooling: 5,000–100,000 (complexity, steel vs. aluminum molds).

- Material: 2–20/kg (e.g., PP vs. PEEK).

- Volume: Higher volumes reduce per-unit costs.

- Lighter Weight: Reduces machinery load and energy costs.

- Corrosion Resistance: No rust in humid or chemical environments.

- Cost Savings: Lower per-part costs for high volumes.

Yes! It’s highly profitable for high-volume orders (10,000+ units) due to economies of scale, especially in automotive, medical, and consumer goods industries.

- Manufacturing: Gears, housings, conveyor components.

- Automation: Sensor casings, robotic arms.

- Energy: Electrical insulators, turbine parts.

- Construction: Heavy-duty tool handles, fasteners.

For 1–500 parts, 3D printing is cheaper. For 1,000+ parts, injection moulding saves up to 80% per unit.

Yes! It’s ideal for:

- High-precision, repeatable parts.

- Mass production with minimal waste.

- Diverse materials (plastics, LSR, metal-polymer blends).

3D-printed molds (e.g., resin or nylon) last 50–200 cycles, vs. steel molds (100,000+ cycles). Best for prototyping, not production.

Yes! Metal Injection Moulding (MIM) uses powdered metal (e.g., stainless steel) mixed with binder for small, complex parts like gears or surgical tools.

- Injection Unit: Melts and injects material.

- Clamping Unit: Holds and closes the mold.

- Control System: Manages temperature, pressure, and cycle times.