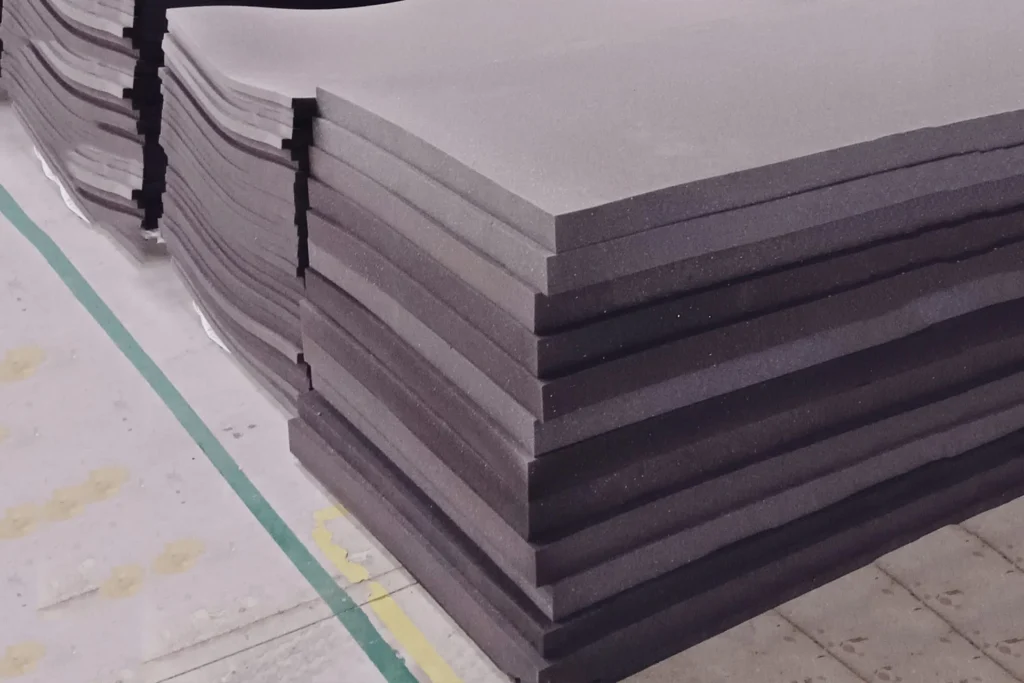

Dhanya Foams specializes in manufacturing high-strength, fire-retardant PU (Polyurethane) foams engineered to meet stringent safety standards across diverse applications. Our expertise lies in formulating and producing foams that not only offer excellent structural integrity and durability but also provide crucial fire safety properties. By adhering to rigorous testing and quality control processes, Dhanya Foams ensures their fire-retardant PU foams comply with relevant industry regulations. This commitment to both strength and safety makes their foams a reliable choice for applications ranging from furniture and bedding to automotive interiors and construction materials, where fire resistance is paramount.

In a world increasingly conscious of safety standards, the demand for effective fire retardant materials is paramount across various industries. Dhanya Foams has emerged as a strong player in the manufacturing of ARAI Approved fire retardant polyurethane (PU) foams, offering a compelling combination of expertise, technology, and commitment to quality. This blog post explores the key strengths that position Dhanya Foams as a reliable partner for businesses seeking superior fire-resistant foam solutions.

1. Deep Understanding of Fire Retardancy in PU Foams:

Manufacturing effective fire retardant PU foams goes beyond simply adding chemicals. Dhanya Foams likely possesses a deep understanding of the intricate science behind flame inhibition in polyurethane materials. This includes:

- Mechanism of Action: We understand how different fire retardant additives interact with the PU polymer matrix during combustion, whether by forming a protective char layer, releasing flame-quenching gases, or disrupting the combustion process at a chemical level.

- Material Compatibility: Our expertise extends to selecting the right type and concentration of fire retardants that are not only effective but also compatible with the specific PU foam formulation, ensuring the desired physical and mechanical properties are maintained.

- Synergistic Blends: Dhanya Foams may utilize synergistic blends of different fire retardant additives to achieve optimal performance, often at lower overall loading levels, which can be beneficial for cost and material properties.

2. Tailored Formulations for Diverse Applications:

Recognizing that fire safety requirements vary significantly across industries, Dhanya Foams likely specializes in developing customized fire retardant PU foam formulations:

- Meeting Specific Standards: We are likely adept at formulating foams that meet various national and international fire safety standards and regulations relevant to different applications (e.g., FMVSS 302 for automotive, UL 94 for electronics, building codes).

- Density and Flexibility Control: Our expertise allows them to incorporate fire retardancy into PU foams of varying densities (from low to high) and flexibility (flexible, semi-rigid, rigid), catering to a wide array of product designs and performance needs.

- Application-Specific Properties: Beyond fire retardancy, we can tailor foam properties like thermal insulation, acoustic absorption, cushioning, and durability to ensure multifunctional utility in products such as ARAI approved Fire Retardant PU Foams used in industrial and automotive sectors.

3. Advanced Manufacturing Processes and Quality Control:

Dhanya Foams’ strength in producing ARAI approved Fire Retardant PU Foams is supported by advanced processes and rigorous quality control measures:

- Precise Chemical Metering and Mixing: The accurate addition and thorough mixing of fire retardant additives during the foaming process are crucial for consistent performance. Dhanya Foams likely employs advanced equipment to ensure precise control over these parameters.

- Controlled Reaction Conditions: Factors like temperature, humidity, and reaction time significantly impact the final foam structure and fire retardant properties. Our manufacturing processes are likely carefully controlled to guarantee uniformity and efficacy.

- Rigorous Quality Testing: Dhanya Foams will have stringent quality control procedures in place to verify the fire retardant properties of our foams. This may involve standard flammability tests, smoke density measurements, and other relevant assessments to ensure compliance and performance.

4. Focus on Innovation and Safety:

Dhanya Foams likely demonstrates a commitment to continuous improvement and safety in our fire retardant foam manufacturing:

- Exploring Newer, Safer Fire Retardants: We may be actively researching and incorporating newer, more environmentally friendly, and less hazardous fire retardant technologies as we become available.

- Optimizing Production for Safety: Our manufacturing processes are likely designed with safety in mind, minimizing risks associated with handling chemicals and producing the foams.

- Collaboration and Knowledge Sharing: Dhanya Foams will engage in collaborations with research institutions or industry experts to stay at the forefront of fire safety advancements in PU foams.

5. Potential Certifications and Compliance:

A key indicator of Dhanya Foams’ strength in this area would be our adherence to relevant certifications and compliance standards:

- ISO Certifications: Holding certifications like ISO 9001 demonstrates a commitment to quality management systems, which is essential for consistent and reliable production of fire retardant materials.

- Fire Safety Standards Compliance: As mentioned earlier, we hold certifications or can provide test reports demonstrating compliance with specific fire safety standards relevant to the target applications of our foams.

Applications of Dhanya Foams’ Fire Retardant PU Foams:

The strength in our manufacturing translates to a wide range of applications where fire safety is critical, potentially including:

- Automotive Industry: Seating, headliners, and interior components requiring FMVSS 302 compliance.

- Furniture and Bedding: Mattresses, upholstery, and cushioning materials meeting fire safety regulations for domestic and commercial use.

- Construction: Insulation materials, gap fillers, and sealants with enhanced fire resistance for buildings.

- Electronics: Components and enclosures requiring UL 94 flammability ratings.

- Aerospace: Interior parts and insulation materials meeting stringent aviation fire safety standards.

- Packaging: Protective packaging for sensitive or flammable goods.

- Specialty Applications: Acoustic panels, thermal insulation in industrial settings, and other areas where fire safety is a concern.

Why ARAI Approval Matters for Automotive PU Foams

For PU foams used in automotive applications (like seating, headliners, interior trims, generator accoustic applications etc.), ARAI approval signifies that these materials have undergone rigorous testing and meet the specific safety and performance standards mandated for use in vehicles in India. This is particularly critical for properties like:

- Flammability/Fire Retardancy: Ensuring that the foams meet the fire safety standards outlined in regulations like FMVSS 302 , UL 94 Class HF1, IS 7888.This testing assesses the material’s resistance to burning and the rate at which it burns, providing crucial escape time for occupants in case of a fire.

- Dhanya Foam manufactured Fire retardant PU foam meet the fire safety standards outlined in regulations like FMVSS 302 , UL 94 Class HF1, IS 7888 which is approved by ARAI.

Dhanya Foams’ strength in manufacturing fire retardant PU foams lies in our in-depth understanding of fire science, our ability to tailor formulations for diverse needs, our commitment to advanced and controlled manufacturing processes, a focus on innovation and safety, and likely adherence to relevant certifications. This multifaceted approach positions us as a trusted supplier of high-quality, reliable fire-resistant PU foam solutions for a wide range of industries where safety is paramount. Businesses seeking to enhance the fire safety of our products can confidently partner with Dhanya Foams to meet and exceed stringent requirements.

Frequently Asked Questions

Fire Retardant PU Foam is a polyurethane foam treated with additives to resist ignition, slow flame spread, and reduce smoke emission. It’s designed to meet stringent fire safety standards, making it ideal for applications where fire risk mitigation is critical.

Unlike standard foam, Fire Retardant PU Foam contains flame-inhibiting additives (e.g., halogen-free compounds) that suppress combustion, emit less toxic smoke, and self-extinguish when the flame source is removed.

- Construction: Insulation for walls, roofs, and HVAC systems.

- Automotive: Seating, headliners, and acoustic panels.

- Furniture: Upholstery for public spaces (hotels, theaters).

- Aerospace: Cabin insulation and cargo liners.

- Spray Foam: Insulates gaps and seals joints in walls/roofs.

- Rigid Panels: Pre-cut boards for thermal and fire barriers.

- Cavity Filling: Injected into voids for firestopping.

Standard polyurethane (PU) foam is flammable, but Fire Retardant PU Foam is chemically treated to resist ignition, slow flame spread, and self-extinguish. Always verify fire ratings (e.g., UL 94 V-0) for safety compliance.

Regular PU foam lacks flame retardants. Fire Retardant PU Foam contains additives like halogen-free compounds, phosphorus, or melamine to suppress combustion and reduce smoke toxicity.

Common fire retardant additives include:

- Ammonium Polyphosphate (for insulation).

- Aluminum Trihydroxide (ATH).

- Brominated/Chlorinated Compounds (halogen-based).

- Intumescent Coatings (swell under heat to form protective char).

Key types include:

- Fire Retardant PU Foam (flexible/rigid).

- Phenolic Foam (high heat resistance).

- Melamine Foam (low smoke emission).

- Cementitious Foam (non-combustible, used in construction).

- Fire Resistant: Materials (e.g., fiberglass, stone wool) resist ignition entirely but are often heavier/costlier.

- Fire Retardant: Materials (e.g., treated PU foam) slow combustion and are lighter/more versatile.

Choose based on application: Fire resistant for structural protection, fire retardant for flexible insulation or upholstery.

Absolutely. Modern formulations use non-toxic, halogen-free additives that comply with REACH and RoHS, ensuring low smoke toxicity and safe indoor air quality.