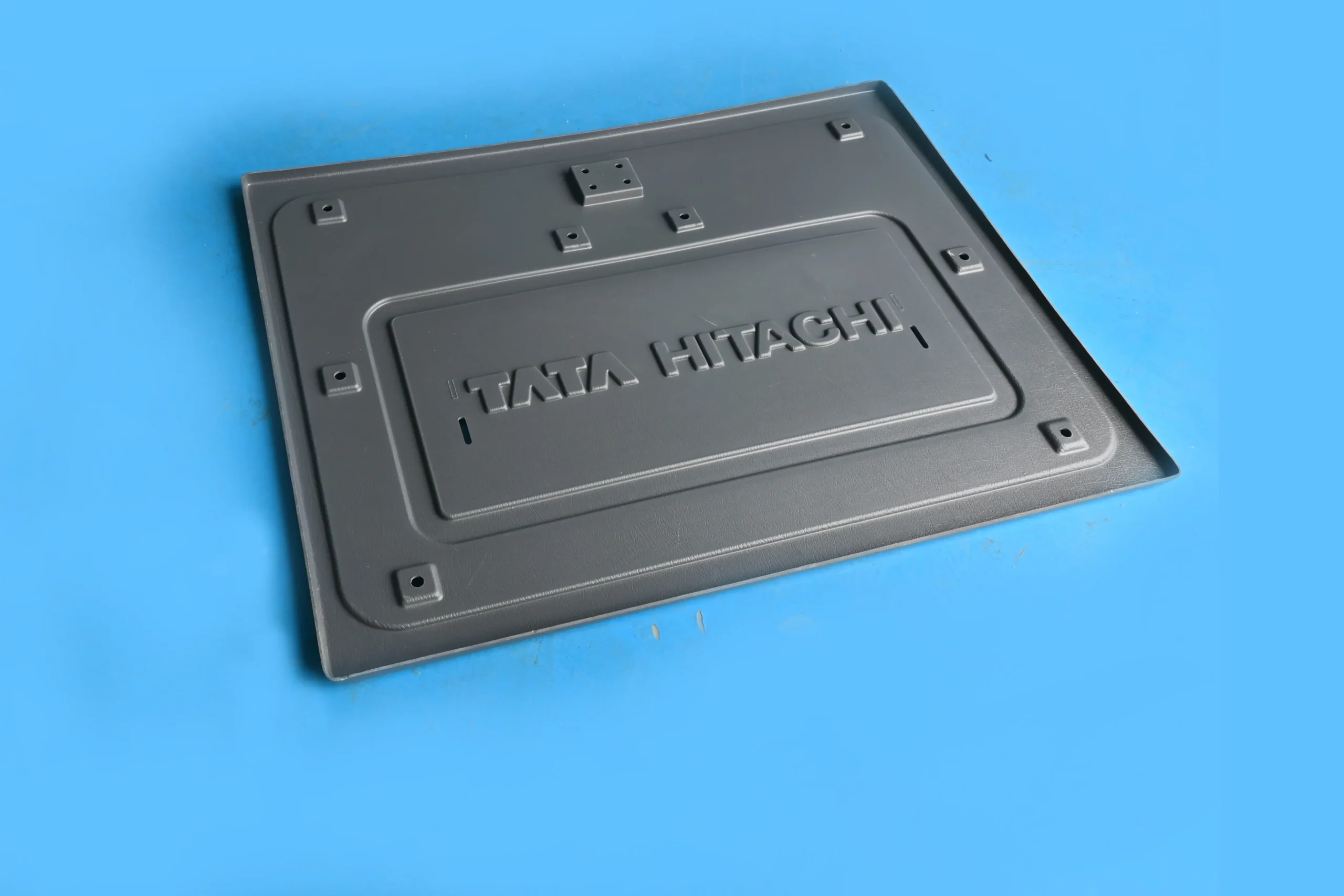

Dhanya Plastics applies its vacuum forming expertise to create robust plastic parts for excavator and construction equipment cabins, understanding the demanding conditions these machines operate in. We prioritize the strength and durability of the formed components to withstand impacts, vibrations, and harsh environmental factors prevalent on construction sites. By selecting high-impact plastics and employing precise vacuum forming techniques, Dhanya Plastics manufactures cabin parts like interior panels, consoles, and roofing that offer long-lasting performance and contribute to operator safety and comfort. Their focus on strength ensures these essential equipment components can endure rigorous use.

In the demanding world of heavy machinery related to construction, the operator’s cabin is more than just a workspace; it’s a command center that requires durability, functionality, and operator comfort. Within these robust structures, seemingly small yet crucial plastic components play a significant role. Dhanya Plastics and Foams Pvt Ltd has carved a niche as a leader in manufacturing high-quality ABS (Acrylonitrile Butadiene Styrene) Interior plastic parts for Excavator cabins using the precision and versatility of vacuum forming.

But what makes Dhanya Plastics the preferred partner for excavator manufacturers seeking these critical interior components? It boils down to a potent combination of material expertise, mastery of the vacuum forming process, a deep understanding of the heavy equipment industry’s demands, and an unwavering commitment to quality. Let’s dig deeper into our strengths:

1. The Power of ABS for Rugged Environments:

Dhanya Plastics’ focus on ABS for Interior plastic parts for Excavator cabins is a strategic choice rooted in the inherent properties of this versatile thermoplastic:

- Exceptional Impact Resistance: Excavators operate in demanding environments where impacts and vibrations are commonplace. ABS boasts excellent impact strength, ensuring that cabin interior parts like panels, consoles, and covers can withstand the rigors of daily use without cracking or breaking.

- Superior Durability: Longevity is crucial for heavy equipment. ABS offers excellent abrasion resistance and can withstand exposure to various environmental factors, ensuring the cabin interior components maintain our integrity over the lifespan of the excavator.

- Dimensional Stability: Maintaining precise dimensions is vital for proper fit and functionality within the cabin. ABS exhibits good dimensional stability, ensuring that vacuum-formed parts retain our shape and integrate seamlessly with other cabin elements.

- Chemical Resistance: Excavator cabins can be exposed to oils, fuels, and cleaning agents. ABS offers good resistance to many common chemicals, ensuring the interior parts remain uncompromised.

- Aesthetics and Finish: Beyond durability, the interior appearance contributes to operator comfort and brand image. ABS offers a good surface finish and can be textured or colored to meet specific design requirements for Interior plastic parts for Excavator cabins.

2. Mastering Vacuum Forming for Complex Cabin Geometries:

Dhanya Plastics’ expertise in vacuum forming is key to translating the robust properties of ABS into intricate and functional Interior plastic parts for Excavator cabins.

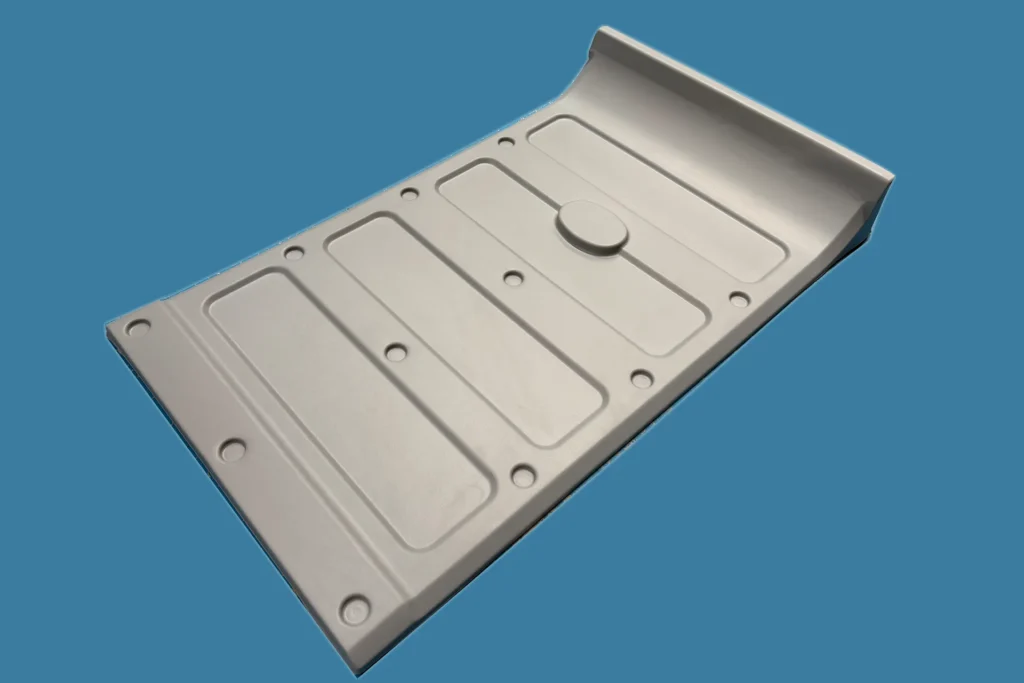

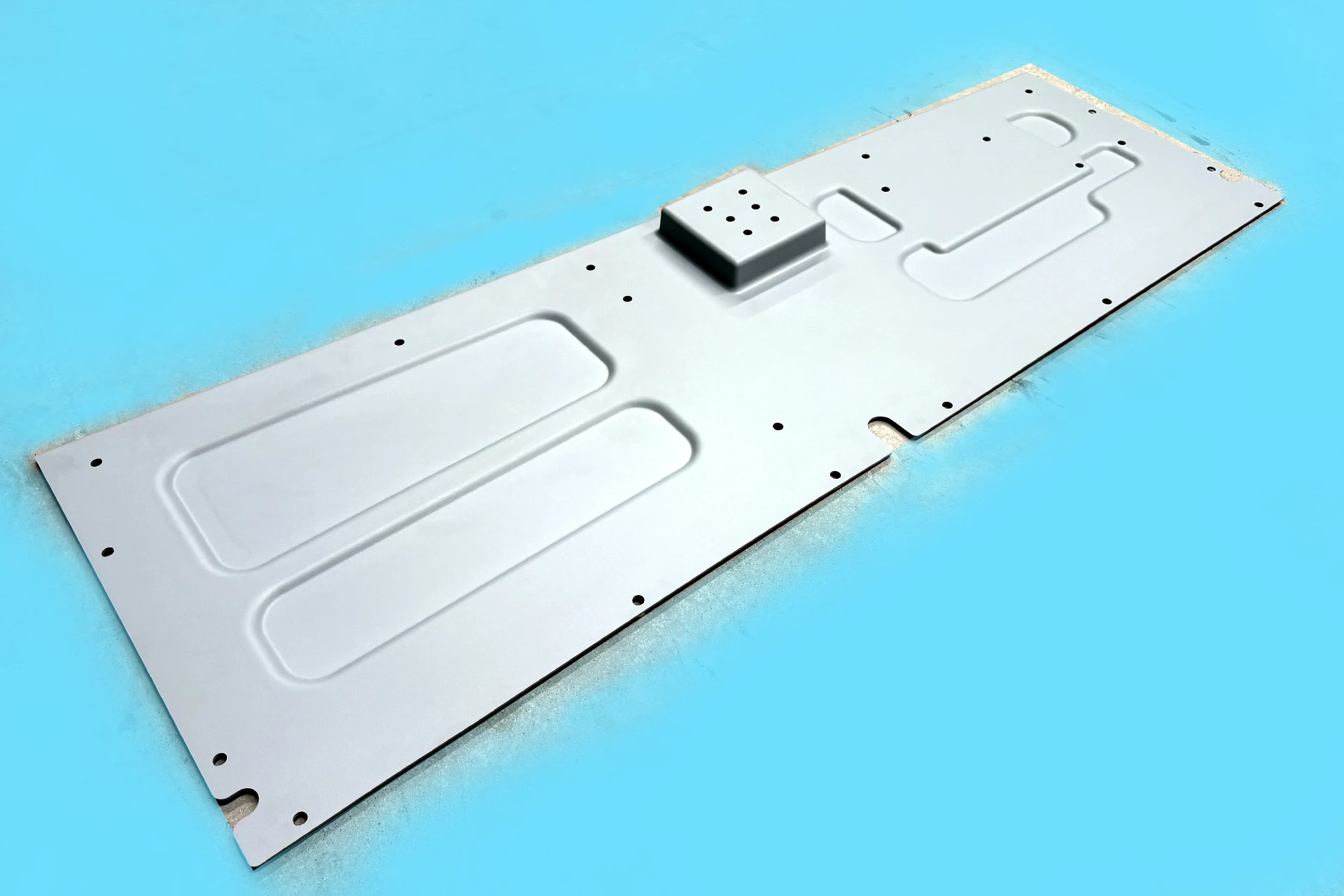

- Precision and Detail: Vacuum forming allows for the creation of parts with complex curves, contours, and integrated features, perfectly matching the ergonomic designs of modern excavator cabins. Dhanya Plastics’ skilled technicians and advanced tooling ensure high precision and detail in every part.

- Consistent Wall Thickness: Achieving consistent wall thickness is crucial for the structural integrity and uniform appearance of the parts. Dhanya Plastics optimized vacuum forming processes ensure even material distribution across the mold, resulting in robust and reliable components.

- Large Part Capability: Excavator cabins often require large interior panels and components. Dhanya Plastics possesses the capacity and expertise to vacuum form large ABS sheets into these sizable parts while maintaining quality and accuracy.

- Cost-Effective for Medium to High Volumes: Vacuum forming offers a cost-effective manufacturing solution for the volumes typically required by excavator manufacturers, providing an efficient way to produce complex ABS parts.

- Rapid Prototyping and Tooling: Dhanya Plastics understands the importance of quick turnaround times in the manufacturing sector. Our capabilities include efficient prototyping and tooling processes, allowing for faster design iterations and quicker time-to-market for new Interior plastic parts for Excavator cabins.

3. Tailored Solutions for Excavator Cabin Interiors:

Dhanya Plastics doesn’t just manufacture parts; we provide tailored solutions that address the specific needs of excavator cabin interiors:

- Operator Comfort Focus: We understand the importance of operator well-being and can manufacture parts that contribute to an ergonomic and comfortable cabin environment, such as armrests, consoles designed for easy access to controls, and interior panels that enhance aesthetics.

- Safety and Functionality Integration: Dhanya Plastics can incorporate features like mounting points for switches, vents, and other essential cabin components directly into the vacuum-formed ABS parts, enhancing functionality and simplifying assembly.

- Durability for Harsh Environments: Our expertise ensures that the manufactured parts can withstand the vibrations, dust, and temperature variations common in excavator operating conditions.

- Custom Colors and Textures: Dhanya Plastics can match specific color requirements and create textured surfaces to enhance the cabin’s appearance and reduce glare.

- Weight Optimization: While maintaining strength, Dhanya Plastics can optimize part designs to minimize weight, contributing to overall excavator efficiency.

4. A Commitment to Quality and Reliability:

Dhanya Plastics’ strength is underpinned by a strong commitment to quality at every stage of the manufacturing process:

- Stringent Material Selection: We source high-grade ABS materials that meet the demanding specifications of the heavy equipment industry.

- Rigorous Quality Control: From initial material inspection to final part verification, Dhanya Plastics employs strict quality control measures to ensure dimensional accuracy, structural integrity, and consistent finish.

- Adherence to Industry Standards: We are committed to meeting relevant industry standards and regulations, providing excavator manufacturers with the assurance of reliable and compliant components.

- Long-Term Partnership Approach: Dhanya Plastics aims to build long-term partnerships with our clients, offering consistent quality, reliable supply, and ongoing support.

Dhanya Plastics stands as a powerful force in the manufacturing of ABS parts for excavator cabin interiors through our mastery of vacuum forming. Our strategic choice of ABS, coupled with our precision in the vacuum forming process and our deep understanding of the heavy equipment industry’s unique demands, positions them as a leader in this specialized field. By providing durable, functional, and aesthetically pleasing interior components, Dhanya Plastics plays a crucial role in enhancing the performance, comfort, and longevity of excavators, truly “excavating excellence” in every part we produce. For excavator manufacturers seeking reliable and high-quality ABS cabin solutions, Dhanya Plastics is a partner we can depend on to build robust and operator-friendly machinery.

Frequently Asked Questions

Vacuum forming creates robust, lightweight parts like machine housings, protective covers, and storage bins by molding heated plastic sheets over custom molds. It’s ideal for construction due to:

- Durability: UV-stabilized and chemical-resistant plastics (e.g., ABS, HDPE) withstand harsh job-site conditions.

- Cost Savings: Lower tooling costs vs. metal fabrication and reduced fuel expenses from lighter components.

- Corrosion Resistance: Plastic parts eliminate rust issues common in metal alternatives.

- ABS: Impact-resistant for machinery guards and dashboards.

- HDPE: UV-stabilized and chemical-resistant for outdoor panels.

- Polycarbonate: Shatterproof for safety shields and windows.

- Fire Retardant PVC: Meets flammability standards for enclosures.

Materials are chosen for resistance to abrasion, UV rays, and chemicals, ensuring longevity in extreme conditions like dust, rain, and temperature fluctuations.

Yes. Reinforced plastics (e.g., glass-filled ABS) and ribbed designs enhance strength for components like equipment housings or storage bins.

Absolutely. Plastics resist rust and chemical corrosion, ideal for humid or chemical-exposed environments like mining or coastal construction sites.

Custom molds and finishes (textured, anti-slip, or branded) allow tailored designs for excavator panels, crane controls, or sensor housings.

- Lighter Weight: Reduces fuel costs and improves portability.

- Faster Turnaround: Lower tooling costs and quicker production.

- No Welding: Seamless designs reduce weak points.

Prototypes: 1–2 weeks. Production: 4–6 weeks (depending on mold complexity and order volume).

High-temp plastics (e.g., polycarbonate) withstand ranges from -40°C to 120°C, suitable for desert or Arctic operations.

- Lower Costs: Ideal for medium/large batches.

- Material Diversity: UV-stable, fire retardant options.

- Surface Finish: Smooth, ready-to-use parts without post-processing.