Dhanya Foams excels in manufacturing high-performance acoustic foams designed to meet specific sound absorption standards across a wide array of applications. Our strength lies in engineering foams with optimal density, porosity, and cell structure to effectively control noise and reverberation. By adhering to industry acoustic testing standards, Dhanya Foams ensures their products deliver reliable sound dampening properties. From recording studios and auditoriums to industrial machinery enclosures and automotive interiors, our acoustic foams provide effective noise management solutions, contributing to improved sound quality and comfort in various environments.

In today’s world, where noise pollution is a growing concern in both residential and commercial spaces, the demand for effective acoustic solutions is on the rise. Dhanya Plastics and Foams Pvt Ltd has positioned itself as a pioneer in manufacturing polyurethane (PU) foams specifically engineered for acoustic applications. Our commitment to innovation, material science, and understanding the nuances of sound absorption and insulation makes them a go-to partner for architects, interior designers, audio engineers, and industries seeking to create quieter and more controlled sound environments.

One of our standout solutions is our Accoustic Foam for Diesel Generator Enclosures-ARAI approved, which meets stringent performance standards for industrial noise reduction and compliance.

This blog post delves into the strengths that establish Dhanya Foams as a leader in the realm of acoustic PU foam manufacturing.

1. Deep Understanding of Acoustic Principles and PU Foam Properties:

Dhanya Foams’ pioneering status stems from our profound understanding of how sound interacts with materials, coupled with our mastery of manipulating PU foam properties for optimal acoustic performance. This involves:

- Sound Absorption Mechanisms: We understand the different ways PU foams can absorb sound energy, primarily through converting sound waves into heat within the cellular structure of the foam. Factors like cell size, density, and airflow resistance are crucial, and Dhanya Foams likely excels at controlling these parameters.

- Sound Insulation Principles: While PU foams are primarily known for absorption, Dhanya Foams may also engineer denser or layered PU foam solutions that contribute to sound insulation by blocking the transmission of sound waves through a barrier.

- Frequency-Specific Performance: Different applications require absorption at different frequencies. Dhanya Foams likely has the expertise to tailor foam formulations and designs to target specific frequency ranges, whether it’s absorbing high-frequency echoes in a recording studio or dampening low-frequency vibrations in industrial settings.

2. Tailored PU Foam Formulations for Diverse Acoustic Needs:

Recognizing the varied demands of acoustic applications, Dhanya Foams likely offers a diverse range of specialized PU foam products:

- Open-Cell Foams for Absorption: These foams, characterized by our interconnected cell structure, are highly effective at absorbing sound waves. Dhanya Foams likely manufactures open-cell foams with optimized porosity and airflow resistance for different levels of absorption.

- Closed-Cell Foams for Insulation and Reflection: While primarily for insulation, denser closed-cell PU foams can offer some sound blocking capabilities and can be used as reflective surfaces in specific acoustic designs. These are often integrated into solutions like Accoustic Foam for Diesel Generator Enclosures-ARAI approved to ensure superior noise reduction performance.

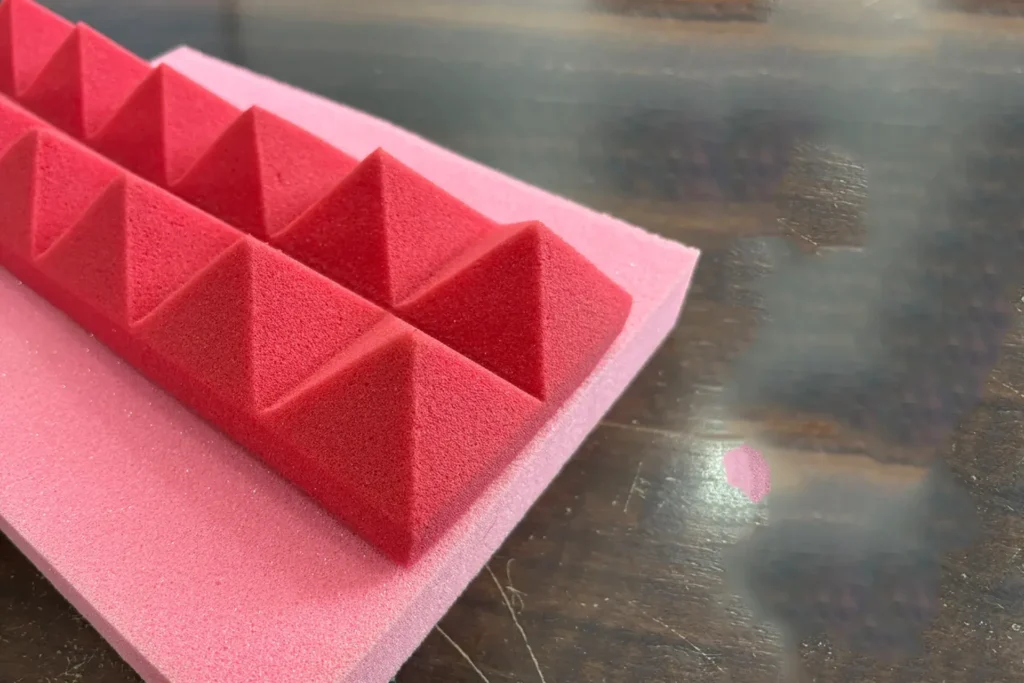

- Convoluted and Profiled Foams: These geometrically shaped foams (e.g, egg-crate, wedge) increase the surface area available for sound wave interaction, enhancing absorption efficiency, particularly at higher frequencies. Dhanya Foams likely has advanced cutting and profiling capabilities to produce these designs with precision.

- Layered and Composite Solutions: For more complex acoustic challenges, Dhanya Foams might manufacture layered or composite materials combining different PU foam types or integrating them with other acoustic materials to achieve specific sound control characteristics.

3. Advanced Manufacturing Techniques for Consistent Acoustic Performance:

Achieving reliable and consistent acoustic performance requires precise manufacturing processes. Dhanya Foams employs advanced techniques to ensure the quality and effectiveness of our acoustic PU foams:

- Controlled Density and Porosity: Maintaining tight control over the density and cell structure of the foam during the manufacturing process is crucial for predictable acoustic properties. This is especially important for applications like Accoustic Foam for Diesel Generator Enclosures-ARAI approved, where consistency ensures compliance with regulatory standards.

- Precise Cutting and Shaping: For profiled foams and custom shapes, accurate cutting and shaping technologies are essential. Dhanya Foams invests in advanced cutting machinery to meet specific design requirements with high precision.

- Adherence to Acoustic Testing Standards: Dhanya Foams conducts rigorous in-house testing according to relevant acoustic standards, such as ARAI’s NRC test standard, to verify the performance of our foams and provide reliable data to our clients. This is a cornerstone of our Accoustic Foam for Diesel Generator Enclosures-ARAI approved solutions.

4. Innovation and Customization for Unique Acoustic Challenges:

As a pioneer, Dhanya Foams likely embraces innovation and offers customization options to address specific acoustic challenges:

- Research and Development: We have a dedicated R&D team exploring new PU foam formulations, additives, and manufacturing techniques to further enhance acoustic performance and explore novel applications.

- Custom Design and Fabrication: Dhanya Foams might work closely with clients to understand our unique acoustic requirements and offer tailored foam solutions in terms of shape, size, density, and absorption characteristics.

- Integration with Other Materials: We explore combining PU foams with other acoustic materials like mass-loaded vinyl or damping compounds to create solutions for complex noise control problems.

5. Applications Across Diverse Industries:

Dhanya Foams’ expertise in acoustic PU foams likely caters to a wide range of industries and applications, including:

- Audio and Recording Studios: Providing high-performance absorption panels, bass traps, and diffusers for optimal sound quality.

- Home Theaters and Entertainment Rooms: Creating immersive audio experiences by controlling reflections and reverberation.

- Architectural Acoustics: Integrating sound-absorbing materials into walls, ceilings, and floors of buildings to improve speech intelligibility and reduce noise levels.

- Industrial Noise Control: Manufacturing foams for machinery enclosures, acoustic barriers, and damping vibrations to create quieter and safer work environments.

- Automotive and Transportation: Providing sound-absorbing and insulating materials for vehicle interiors to enhance passenger comfort.

- HVAC and Equipment: Damping vibrations and reducing noise from ventilation systems and other mechanical equipment.

- OEM Components: Supplying custom-engineered acoustic foam parts for various product manufacturers.

Dhanya Foams’ pioneering status in manufacturing PU foams for acoustic applications is built upon a strong foundation of material science, a deep understanding of acoustic principles, advanced manufacturing capabilities, a commitment to innovation, and a customer-centric approach. Our ability to tailor foam formulations and designs to meet diverse acoustic needs across various industries positions them as a leader in creating quieter, more controlled, and sonically optimized environments. For those seeking effective and reliable acoustic solutions, Dhanya Foams stands as a trusted and experienced partner.

Frequently Asked Questions

Acoustic foam is a lightweight, porous material designed to absorb sound waves, reducing echoes, reverberation, and background noise. Its open-cell structure traps sound energy, making it ideal for studios, offices, theaters, and industrial spaces.

- Polyurethane (PU) Foam: Flexible, cost-effective, and customizable.

- Melamine Foam: Fire resistant and highly durable for harsh environments.

- Polyester Fiber: Eco-friendly alternative for residential use.

- Entertainment: Recording studios, cinemas.

- Commercial: Open-plan offices, conference rooms.

- Industrial: Factories, HVAC systems.

- Residential: Home theaters, bedrooms.

Acoustic foam has an open-cell structure and specialized shapes (e.g., wedges, pyramids) to maximize sound absorption, unlike standard foam, which lacks noise-reduction properties.

No. It reduces echoes and mid-to-high-frequency noise (voices, machinery). For low-frequency sounds (bass), combine with mass-loaded vinyl or soundproof barriers.

Yes. Custom-cut panels, shapes (egg crate, pyramid), and colors are available to match aesthetic or functional needs.

- 2–4 cm: For basic echo reduction in small rooms.

- 5–10 cm: For studios or industrial noise control.

- Bass Traps: 10+ cm for low-frequency absorption.

- Adhesive Spray/Mounting Tape: For walls/ceilings.

- Frames/Rigid Panels: For modular systems.

- Freestanding Panels: For flexible setups.

High-density PU or melamine foam lasts 5–10+ years. Avoid direct sunlight and moisture to prolong lifespan.

- Weight: Foam is lighter and easier to install.

- Safety: Foam doesn’t release irritants like fiberglass.

- Aesthetics: Foam offers decorative finishes.