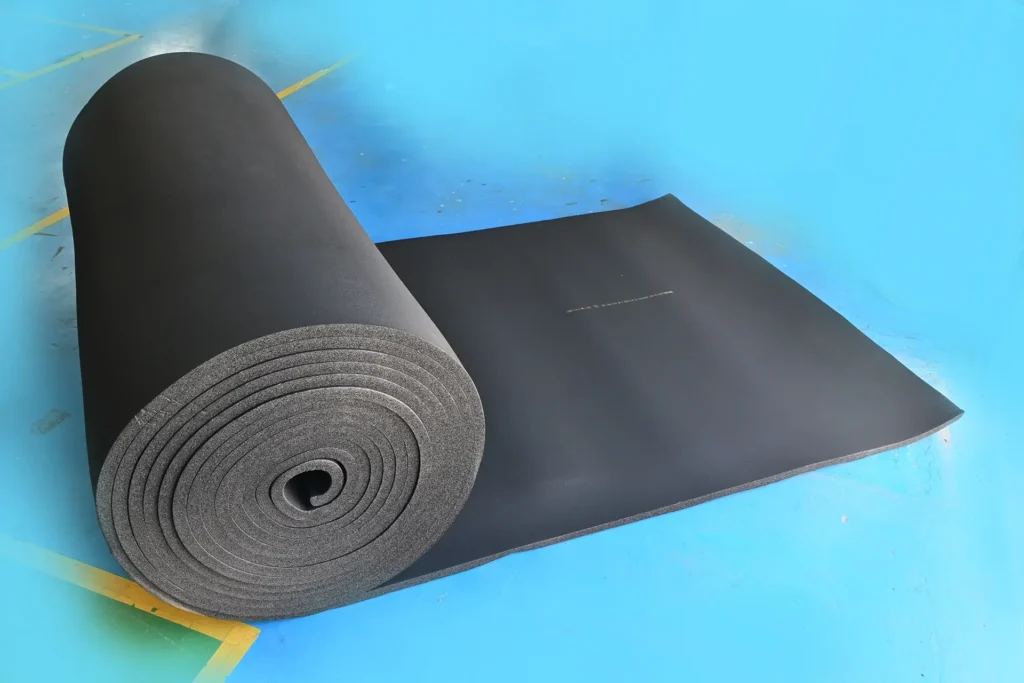

Dhanya Foams is a strong supplier of nitrile foam solutions for a broad spectrum of industrial applications, often with the added convenience of integrated adhesive coatings. Our nitrile foam stands out for its excellent resistance to oils, fuels, and many chemicals, along with its durability and sealing properties. Dhanya Foams ensures consistent quality in their nitrile foam supply, offering it in various thicknesses and densities to meet specific industrial needs. By also providing adhesive-backed options, We offer a practical and efficient solution for applications requiring reliable sealing, cushioning, or insulation in demanding environments. This combination of material performance and application convenience makes Dhanya Foams a dependable source for industrial nitrile foam needs.

Nitrile foam, a synthetic rubber-based material, stands out for its exceptional resistance to oils, fuels, and various chemicals. This key property, coupled with its flexibility, durability, and insulation capabilities, makes it an invaluable resource across a diverse range of industries. Dhanya Foams, with its commitment to material excellence and customized solutions, is a supplier of nitrile foam, catering to the specific demands of numerous sectors.

Let’s explore the unique strengths of nitrile foam and its widespread applications:

The Defining Properties of Nitrile Foam:

The versatility of nitrile foam for industrial applications stems from its unique combination of characteristics:

- Excellent Oil and Fuel Resistance: This is its hallmark property, making it ideal for applications involving contact with hydrocarbons.

- Good Chemical Resistance: It withstands exposure to many acids, alkalis, and solvents.

- Wide Temperature Range: Nitrile foam can typically perform well across a broad temperature spectrum, from low to moderately high temperatures.

- Durability and Abrasion Resistance: It offers good resistance to wear and tear, ensuring longevity in demanding environments.

- Flexibility and Conformability: Its inherent flexibility allows it to conform to irregular surfaces, making it excellent for sealing and gasketing.

- Good Tensile Strength: Providing structural integrity for various applications.

- Insulation Properties: Depending on its density and cell structure (closed-cell being a better insulator), it offers thermal and acoustic insulation.

- Water and Moisture Resistance (Closed-Cell): Closed-cell nitrile foam exhibits excellent resistance to water absorption, making it suitable for sealing and marine applications.

- Flame Retardant Options: Nitrile foam can be formulated to meet specific flame retardancy standards, enhancing safety in various applications.

Tailoring Nitrile Foam for Diverse Industrial Needs:

Dhanya Foams supplies nitrile foam for industrial applications that meet the precise requirements of diverse sectors:

- Custom Formulations: We can tailor the nitrile content and other additives to optimize specific properties like oil resistance, temperature range, and flexibility for particular applications.

- Variety of Densities and Hardness: Offering nitrile foam in different densities and hardness levels to suit requirements ranging from soft cushioning to firm sealing.

- Die-Cutting and Fabrication: Providing precision-cut gaskets, seals, pads, and custom shapes to seamlessly integrate into various products and systems.

- Adhesive Backing and Lamination: Applying adhesive layers for easy installation or laminating with other materials to enhance functionality.

- Open-Cell and Closed-Cell Options: Manufacturing both open-cell (for sound absorption and filtration in some cases) and closed-cell (for superior sealing and insulation) nitrile foams.

- Compliance with Industry Standards: Ensuring our nitrile foams meet relevant industry specifications and safety regulations.

Nitrile Foam: A Workhorse Across Industries:

The unique properties of nitrile foam for industrial applications make it indispensable in a broad range of sectors:

1. Automotive and Aerospace:

- Seals and Gaskets: Critical for preventing leaks of oil, fuel, and hydraulic fluids in engines, transmissions, and fuel systems.

- Hoses and Tubing: Used in fuel lines, oil lines, and other fluid transfer applications due to its chemical resistance.

- Vibration Dampening and Noise Reduction: Employed in various components to reduce noise and vibration.

- Protective Padding: Used in interior components for cushioning and safety.

2. Industrial Manufacturing:

- Seals and Gaskets: For machinery, pumps, compressors, and other equipment handling oils, solvents, and chemicals.

- Conveyor Belts: In applications where resistance to oils and abrasion is required.

- Protective Gloves: Providing excellent chemical and puncture resistance for workers handling hazardous materials.

- Tool Grips and Handles: Offering a comfortable and oil-resistant grip.

- Anti-Vibration Mounts: Reducing noise and vibration from machinery.

3. Oil and Gas:

- Seals and Gaskets: In drilling equipment, pipelines, and processing plants where resistance to crude oil, natural gas, and various chemicals is essential.

- Hoses and Tubing: For transferring various fluids and gases.

- Pipe Insulation: Providing thermal insulation and protection against corrosion.

4. HVAC (Heating, Ventilation, and Air Conditioning) and Refrigeration:

- Insulation: For pipes, ducts, and equipment to prevent heat loss or gain and control condensation. Closed-cell nitrile foam is particularly effective here due to its moisture resistance.

- Seals and Gaskets: Ensuring airtight seals in ductwork and equipment.

5. Construction:

- Sealing and Weatherstripping: Providing airtight and watertight seals around windows, doors, and other openings.

- Expansion Joints: Accommodating movement in concrete and other structures.

- Acoustic Insulation: Reducing sound transmission through walls and floors (open-cell options).

6. Medical and Pharmaceutical:

- Medical Gloves: Offering a latex-free alternative with good chemical and puncture resistance.

- Seals and Gaskets: In medical devices and equipment where chemical compatibility is crucial.

7. Marine:

- Seals and Gaskets: Resistant to saltwater, fuels, and oils in marine engines and equipment.

- Hose and Tubing: For fuel and fluid transfer in marine vessels.

- Flotation Devices: Closed-cell nitrile foam can provide buoyancy.

8. Consumer Goods:

- Yoga Mats and Exercise Equipment: Providing a durable, non-slip, and comfortable surface.

- Shoe Insoles and Padding: Offering cushioning and support.

- Sponges and Wipes: For cleaning applications where oil and chemical resistance is beneficial.

Dhanya Foams: Your Reliable Nitrile Foam Partner:

With its expertise in foam manufacturing and customization capabilities, Dhanya Foams is a strong supplier for industries seeking high-quality nitrile foam solutions. Our commitment to understanding specific application needs and delivering tailored products ensures that our nitrile foam contributes to enhanced performance, safety, and longevity across a wide spectrum of industrial applications.

By choosing Dhanya Foams, businesses gain access to a reliable source of nitrile foam that can be precisely engineered to meet our unique challenges and requirements, ensuring unyielding protection and performance in demanding environments.

Frequently Asked Questions

Nitrile foam, also known as NBR (Nitrile Butadiene Rubber) foam, is a closed-cell elastomeric material renowned for its excellent resistance to oils, fuels, and chemicals. Its closed-cell structure provides superior thermal insulation, moisture resistance, and cushioning properties, making it ideal for various industrial applications.

With low thermal conductivity, nitrile foam effectively reduces heat transfer, making it ideal for insulating pipes, ducts, and equipment in HVAC and refrigeration systems.

Absolutely. Nitrile foam’s dense structure absorbs sound waves, making it effective for noise reduction in industrial and commercial settings.

Yes, nitrile foam possesses inherent flame-retardant properties, making it suitable for applications requiring fire resistance.

Yes, Nitrile foam can be customized in terms of size, thickness, density, and adhesive options to meet unique application needs.