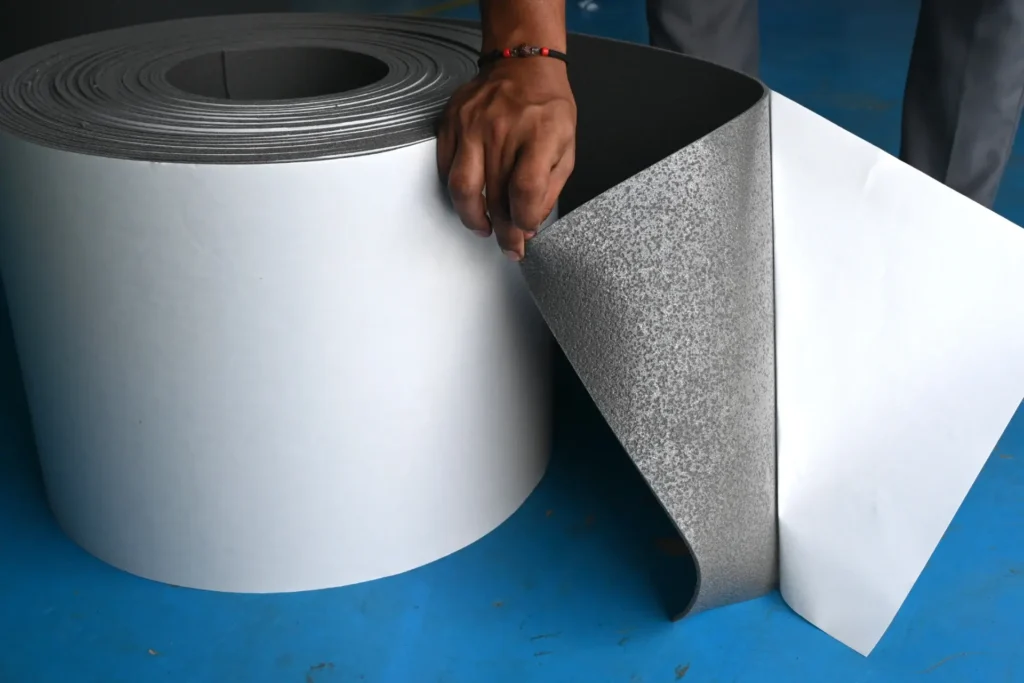

Dhanya Foams is a strong provider of both EVA (Ethylene-Vinyl Acetate) and XLPE (Cross-linked Polyethylene) foams, catering to a wide array of industrial applications with the added benefits of adhesive backing and custom die-cutting.

EVA Foam: Dhanya Foams supplies EVA foam known for its flexibility, cushioning properties, good impact resistance, and vibrant color options. This makes it suitable for applications ranging from protective padding and seals to sports equipment and crafts.

XLPE Foam: Our XLPE foam offers enhanced properties including superior dimensional stability, chemical resistance, and thermal insulation. It’s ideal for more demanding applications such as automotive seals, construction insulation, and protective packaging.

Dhanya Foams ensures consistent quality in both their EVA and XLPE foam supplies. Our ability to apply durable adhesives and provide precise die-cut shapes offers customers tailored and easy-to-use solutions for various needs, streamlining assembly and improving product quality across diverse industries. This comprehensive service makes them a reliable source for adaptable foam solutions.

EVA Foam Suppliers in India: In a world driven by innovation, materials that combine versatility, durability, and sustainability are the backbone of countless industries. Among these, Ethylene-Vinyl Acetate (EVA) foam stands out as a game-changer. From cushioning your favorite sneakers to enabling breakthroughs in renewable energy, EVA foam’s applications are as diverse as we are transformative. At Dhanya Plastics & Foams Pvt Ltd, we take pride in being at the forefront of this revolution, delivering high-quality EVA foam solutions tailored to meet the evolving needs of modern businesses.

What Makes EVA Foam a Material of Choice?

EVA foam is a closed-cell, lightweight material renowned for its shock absorption, thermal insulation, and water-resistant properties. Its unique blend of elasticity and rigidity makes it ideal for industries demanding precision and reliability. Unlike traditional materials, EVA foam is:

- Customizable: Easily molded into complex shapes.

- Eco-Friendly: Recyclable and free from harmful chemicals like CFCs.

- Cost-Efficient: Durable with a long lifecycle, reducing replacement costs.

But what truly sets EVA foam apart is its adaptability. Whether it’s enhancing athletic performance or protecting sensitive electronics, this material bridges the gap between functionality and innovation.

Diverse Applications of EVA Foam

The versatility of EVA foam has led to its adoption in multiple industries:

1. Footwear Industry

EVA foam is a staple in the footwear sector, particularly in midsoles and insoles, providing comfort and shock absorption. Its lightweight nature ensures ease of movement, making it a preferred choice for athletic and casual shoes.

2. Sports & Recreation

From yoga mats to protective gear, EVA foam’s cushioning and durability make it ideal for sports equipment. Its ability to absorb impact reduces the risk of injuries during physical activities.

3. Automotive Sector

In vehicles, EVA foam is used for insulation, sealing, and cushioning components. Its resistance to temperature fluctuations and chemicals ensures longevity and performance.

4. Packaging Solutions

EVA foam provides excellent protection for delicate items during transportation. Its shock-absorbing properties safeguard products from damage, making it a reliable packaging material.

5. Construction & Building

In construction, EVA foam serves as an effective insulator and sealant. Its soundproofing capabilities enhance building acoustics, while its thermal insulation contributes to energy efficiency.

6. Medical Applications

EVA foam is utilized in orthotic devices and prosthetics due to its comfort and adaptability. Its hypoallergenic nature ensures safety for medical applications.

Why Dhanya Plastics & Foams Pvt Ltd is Your Ideal EVA Foam Supplier

In a competitive market, choosing the right supplier is critical. Here’s how Dhanya Plastics & Foams Pvt Ltd stands apart as your trusted EVA foam partner:

Unmatched Expertise in Sourcing & Customization

With decades of experience in the polymer industry, we specialize in sourcing premium-grade EVA foams tailored to your unique requirements. Our deep-rooted relationships with certified global manufacturers allow us to deliver bespoke EVA foam solutions that align with your specifications. Whether you need adjustments in density, thickness, color, or surface texture, our technical team collaborates closely with trusted production partners to ensure every product meets your exact needs.

Our expertise extends beyond procurement—we act as your strategic advisor, helping you select the right foam grade for applications ranging from automotive insulation to medical devices.

Sustainability-Driven Sourcing Practices

As advocates for environmental responsibility, we prioritize partnering with manufacturers who adhere to eco-conscious practices. The EVA foams we supply are recyclable, non-toxic, and free from harmful chemicals like CFCs. We rigorously vet our manufacturing partners to ensure we comply with global sustainability standards, including waste reduction, energy-efficient production, and ethical labor practices.

By choosing Dhanya, you’re not just procuring materials—you’re supporting a greener supply chain.

Customer-Centric Partnership Model

We don’t just supply materials—we build long-term partnerships. Our role as suppliers goes beyond transactions:

- End-to-End Support: From understanding your project goals to coordinating prototypes and bulk orders, we streamline the process.

- Quality Assurance: Every batch of EVA foam undergoes stringent quality checks to ensure it meets industry benchmarks for durability, flexibility, and safety.

Future-Ready Solutions: Staying Ahead of Industry Trends

The EVA foam industry is evolving with innovations like bio-based EVA (made from renewable resources) and smart foams integrated with sensors for applications in wearable tech and ergonomic design. While we don’t manufacture, we stay ahead of the curve by collaborating with innovators and R&D-driven producers.

At Dhanya, we continuously update our portfolio to include cutting-edge foams, such as:

- Anti-static EVA for electronics packaging.

- Flame-retardant grades for automotive and aerospace.

- UV-resistant variants for renewable energy projects.

By keeping our finger on the pulse of emerging trends, we ensure you have access to the latest materials without compromising on quality or lead times.

Choosing the Right EVA Foam Supplier

Selecting an appropriate EVA foam supplier requires careful consideration of multiple factors beyond price. Technical expertise, manufacturing capabilities, quality assurance processes, and customer support services all play crucial roles in determining supplier suitability. Established companies like Dhanya Plastics & Foams Pvt Ltd bring decades of experience and proven track records that provide confidence in long-term partnerships.

The best suppliers offer comprehensive technical support, helping customers select optimal foam specifications for our specific applications. This collaborative approach ensures that projects achieve our performance objectives while maintaining cost efficiency.

EVA foam’s remarkable combination of properties continues to drive innovation across numerous industries. As applications become more sophisticated and demanding, the importance of partnering with experienced, reliable suppliers becomes increasingly critical. The future of EVA foam looks bright, with continued technological advances promising even greater possibilities for this versatile material.

Whether you’re developing next-generation automotive components, designing innovative sports equipment, or creating protective packaging solutions, EVA foam offers the performance characteristics and reliability that modern applications demand.

Frequently Asked Questions

EVA (Ethylene-Vinyl Acetate) foam is a closed-cell foam known for its softness, flexibility, and durability. It offers excellent cushioning, shock absorption, and resistance to water, making it suitable for various applications.

EVA foam is characterized by:

- Flexibility and softness

- Excellent shock absorption

- Water and moisture resistance

- UV resistance

- Lightweight nature

- Good thermal insulation

EVA foam is widely used in:

- Footwear midsoles and insoles

- Sports equipment padding

- Protective packaging

- Crafts and cosplay props

- Automotive interiors

- Acoustic insulation

EVA foam’s closed-cell structure provides effective sound insulation, making it suitable for acoustic applications to reduce noise and vibrations.

Yes, EVA foam is water-resistant due to its closed-cell structure, preventing water absorption and making it ideal for marine and outdoor applications.

Traditional EVA foam is non-biodegradable. However, eco-friendly variants made from bio-based materials, such as algae, are available, offering more sustainable

Yes, EVA foam is non-toxic and commonly used in children’s toys, play mats, and educational materials due to its safety and cushioning properties.

Absolutely. EVA foam can be produced in various colors and can be easily cut or molded into different shapes, making it versatile for custom applications.