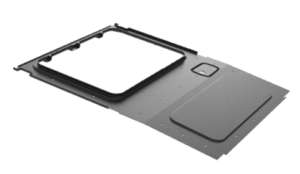

VACUUM FOAMED PARTS

Thermoforming is one of the oldest methods of processing plastic materials. Vacuum-formed products are all around us and play a major part in our daily lives. A sheet of plastic material is heated to pliability and then pressed against a 3D mold by vacuuming out the air between the sheet, and the mold. In other words, Vacuum Forming is where a sheet of plastic is heated to a forming temperature, stretched onto a single-surface mold, and forced against the mold by a vacuum. This process can be used to form plastic into permanent objects such as turnpike signs and protective covers.

WHAT IS ABS ?

ADVANTAGES OF ABS

Acrylonitrile Butadiene Styrene (ABS) is a common thermoplastic used to make automotive body parts, such as Dashboards, Hatrack ducts, Interiors, and many other products.

ABS material has both strength and toughness. The most important mechanical properties of ABS are impact resistance and toughness. A variety of modifications can be made in its constituents to improve impact resistance, toughness, and heat resistance. Stability under load is excellent with limited loads. Thus, changing the proportions of its constituents ABS can be prepared in different grades. There are many textures and colors and even UV and FR material are also available.

KEY ADVANTAGES

PERFECT FOR

- Cost-Effective

- Quicker Tooling

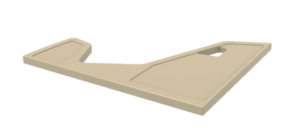

- Ability To Form Very Large Parts

- Sharper Details

- Allows for Undercuts

- Tighter Tolerances

- Allows for Molded-In Texture

OFTEN USED TO CREATE

- Point-of-Purchase Displays

- Automotive Aftermarket - Interior/Exterior

- Recreational Vehicles